Как работает бериллиевая медь с ЧПУ?

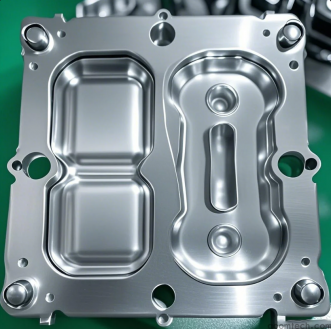

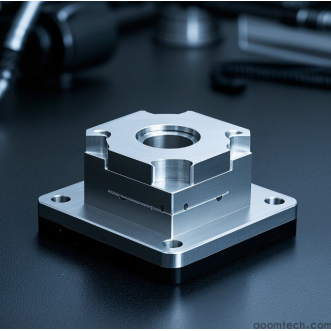

Бериллиевая медь - это высокопроизводительный сплав, широко используемый в аэрокосмической промышленности, электронике и точном машиностроении благодаря своей исключительной прочности, проводимости и термической стабильности. ЧПУ - обработка этого материала требует специальных методов, чтобы обеспечить размерную точность и целостность поверхности. В качестве надежного изготовителя ЧПУ - точной обработки, AOOM Technologies использует современное оборудование и экспертизу в процессах, чтобы изготовить безупречные компоненты из бериллиевой меди.

Основные проблемы при ЧПУ - обработке бериллиевой меди

Износ инструмента: Абразивность сплава ускоряет износ инструмента, поэтому требуются режущие части из карбида или с покрытием из алмазного состава.

Управление теплом: Избыточное тепло может изменить свойства материала, поэтому требуются оптимизированные стратегии охлаждения.

Безопасность: Во время обработки образуются мелкие частицы пыли, поэтому необходимо обеспечить правильное вентилирование и использовать индивидуальные средства защиты.

Проверенный процесс обработки AOOM

Наши услуги ЧПУ - обработки следуют строгому рабочего процессу для бериллиевой меди:

Подготовка материала: Предварительная отжигка для снятия внутренних напряжений, чтобы минимизировать деформацию

Оптимизация траектории инструмента: Адаптивные траектории инструмента с уменьшенными шагами для равномерной нагрузки на инструмент

Применение охлаждающей жидкости: Высокодавляющая охлаждающая жидкость для контроля температуры резания

Обработка после производства: Электрополировка или пассивация для повышения коррозионной стойкости

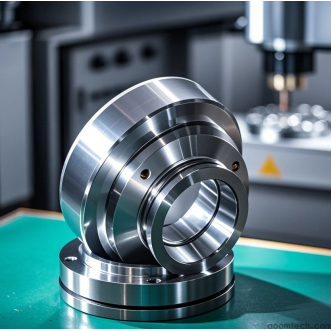

Почему выбирать AOOM для компонентов из бериллиевой меди?

• Контроль качества, сертифицированный по ISO 9001

• 5 - осьевые ЧПУ - станки с допусками 0,005 мм

• Отслеживание материала и отчеты о полноразмерном контроле

• Возможность от создания прототипа до крупномасштабного производства

Свяжитесь с AOOM Technologies по адресу www.aoomtech.com для своих самых требовательных проектов по обработке бериллиевой меди. Наша инженерная команда предоставляет анализ DFM и экономически эффективные решения, адаптированные к вашим спецификациям.

Как найти надежного партнера для высокоточной блистерной алю

Как найти надежного партнера для высокоточной блистерной алю

Ваше руководство по прецизионной обработке оборудования с ЧП

Ваше руководство по прецизионной обработке оборудования с ЧП

Сколько стоит мелкосерийная обработка с ЧПУ для пользователь

Сколько стоит мелкосерийная обработка с ЧПУ для пользователь

Практическое руководство по мелкосерийной обработке с ЧПУ: с

Практическое руководство по мелкосерийной обработке с ЧПУ: с