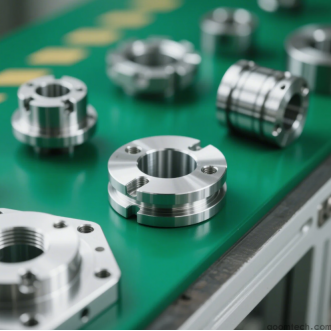

Procesi i përpunimit të grumbullit CNC për pjesët e aluminit

Si një udhëheqës CNC machining service provider, AOOM Technologies specializes in high-volume aluminum component manufacturing with precision and efficiency. This article will explore the critical aspects of CNC batch machining for aluminum parts, addressing the key concerns of procurement managers and engineers.

Kuptimi i Machining CNC për alumini

Batch machining i referohet prodhimit të komponentëve identikë të aluminit në sasi të paracaktuara duke përdorur teknologjinë CNC. Në AOOM, ne punësojmë të avancuara 3/4/5 -axis CNC makina të afta për trajtimin e aliazheve të aluminit nga 100 në 700 seri, duke siguruar saktësi dimensionale brenda ± .01mm.

Hapat kryesorë të procesit

1. Material Preparation: Selection of appropriate aluminum grade based on mechanical requirements

2. Fixture Design: Custom workholding solutions for batch consistency

3. Toolpath Optimization: CAM programming for maximum material removal rates

4. Quality Control: In-process inspection with CMM and surface roughness testers

Avantazhet e Shërbimit tonë Batch Machining

• Cost-effective production for quantities from 50-10,000+ units

• 15-30% faster cycle times through optimized tooling strategies

• Dedicated production cells for aluminum-specific machining

• ISO 9001-certified quality management system

Aplikacionet e industrisë

Aftësitë tona batch machining shërbejnë:

- Aerospace: Structural components and housings

- Automotive: Engine parts and transmission elements

- Electronics: Heat sinks and enclosures

- Medical: Instrumentation components

Me mbi 12 vjet përvojë të përpunimit të aluminit, AOOM Technologies ofron të besueshme CNC batch machining solutions that balance precision, speed, and cost-efficiency. Contact our engineering team today to discuss your specific project requirements.

CNC Pjesë Machining Prodhuesi

CNC Pjesë Machining Prodhuesi

Çfarë Produkte Mund CNC Machine

Çfarë Produkte Mund CNC Machine

CNC Beryllium Procesi i përpunimit të bakrit

CNC Beryllium Procesi i përpunimit të bakrit

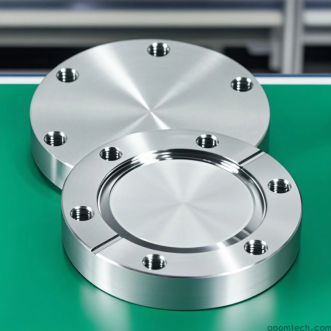

Flange Plate CNC Procesi i përpunimit

Flange Plate CNC Procesi i përpunimit