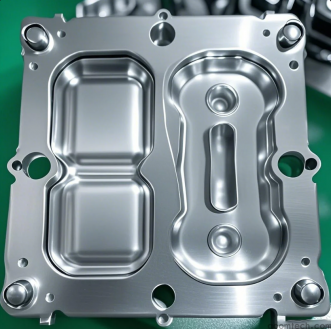

CNC-batchbearbetningsprocess för aluminiumdelar

Som ledande CNC machining service provider, AOOM Technologies specializes in high-volume aluminum component manufacturing with precision and efficiency. This article will explore the critical aspects of CNC batch machining for aluminum parts , addressing the key concerns of procurement managers and engineers.

Förstå CNC-batchbearbetning för aluminium

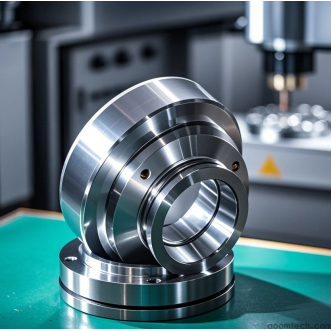

Batchbearbetning avser produktion av identiska aluminiumkomponenter i förutbestämda kvantiteter med hjälp av CNC-teknik. På AOOM använder vi avancerade 3/4/5 CNC-maskiner som kan hantera aluminiumlegeringar från 100 till 700-serien, vilket säkerställer dimensionell noggrannhet inom ± .01mm.

Viktiga processsteg

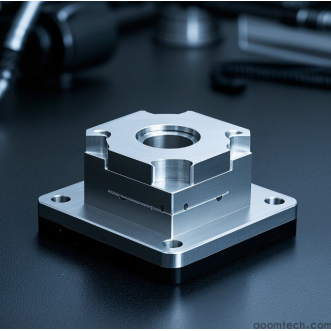

1. Material Preparation : Selection of appropriate aluminum grade based on mechanical requirements

2. Fixture Design : Custom workholding solutions for batch consistency

3. Toolpath Optimization : CAM programming for maximum material removal rates

4. Quality Control : In-process inspection with CMM and surface roughness testers

Fördelar med vår batchbearbetningstjänst

• Cost-effective production for quantities from 50-10,000+ units

• 15-30% faster cycle times through optimized tooling strategies

• Dedicated production cells for aluminum-specific machining

• ISO 9001-certified quality management system

Branschapplikationer

Våra batchbearbetningsmöjligheter tjänar:

- Aerospace: Structural components and housings

- Automotive: Engine parts and transmission elements

- Electronics: Heat sinks and enclosures

- Medical: Instrumentation components

Med över 12 års erfarenhet av aluminiumbearbetning levererar AOOM Technologies pålitliga CNC batch machining solutions that balance precision, speed, and cost-efficiency. Contact our engineering team today to discuss your specific project requirements.

Hur man hittar en pålitlig partner för högprecisionsblister

Hur man hittar en pålitlig partner för högprecisionsblister

Din guide till anpassningstjänster för precisionshårdvara CN

Din guide till anpassningstjänster för precisionshårdvara CN

Hur mycket kostar små partier CNC-bearbetning för anpassade

Hur mycket kostar små partier CNC-bearbetning för anpassade

En praktisk guide till liten sats CNC-bearbetning: Kostnad,

En praktisk guide till liten sats CNC-bearbetning: Kostnad,