CNC Aluminium Produktbearbetning Offert

Vid inköp CNC aluminum product processing services, understanding the quotation factors becomes critical for procurement managers and engineers. As a leading CNC machining service provider, AOOM Technology delivers transparent pricing while maintaining ISO-certified quality standards.

Viktiga faktorer som påverkar CNC-aluminiumbearbetningskostnader

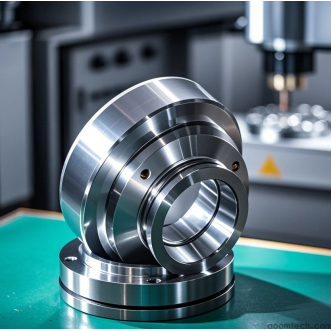

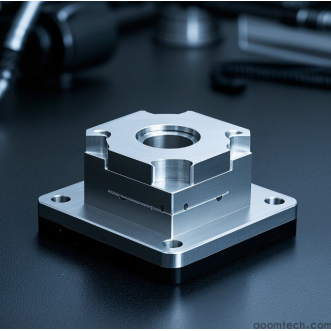

1. Material Specifications : Different aluminum alloys (6061, 7075, etc.) and stock sizes directly impact material costs.

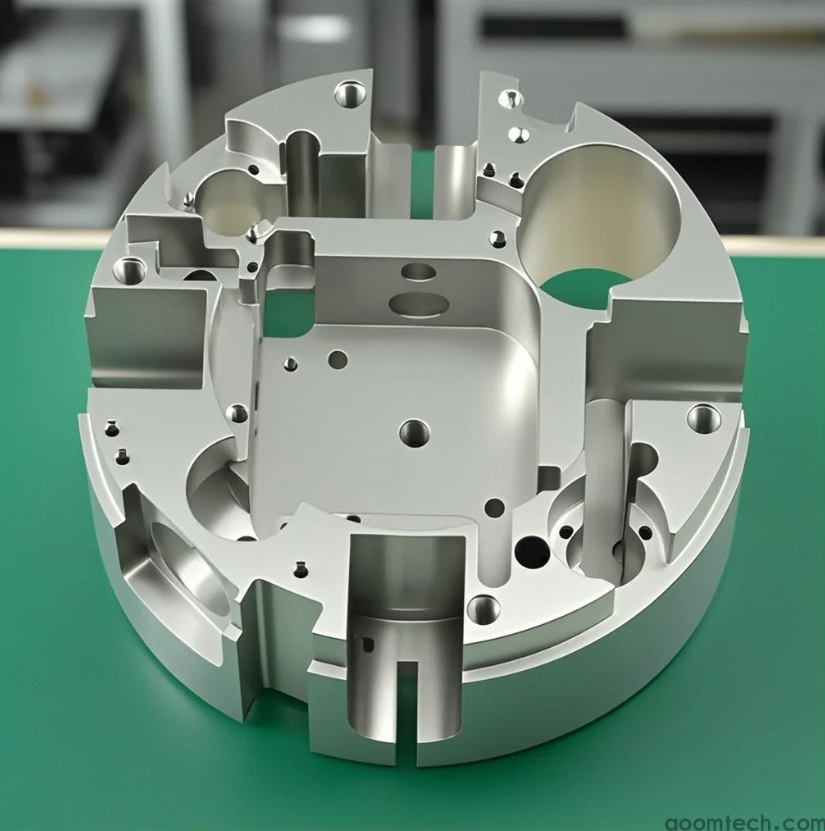

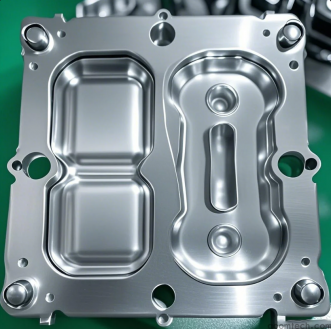

2. Design Complexity : Intricate geometries requiring multi-axis machining or tight tolerances (±.01mm) increase processing time.

3. Surface Treatment : Anodizing, powder coating, or other finishes add post-processing expenses.

AOOMs konkurrensfördelar i prissättningen

Våra CNC machining quotation system offers:

- Real-time online quoting through our proprietary platform

- Volume discounts for batch production (100+ pieces)

- DFM analysis to optimize designs for cost efficiency

Hur man får exakta offerter snabbare

1. Ge fullständiga 3D-ritningar (STEP / IGES-format föredras)

2. Specify required tolerances and surface roughness

3. Indicate annual projected volumes

4. Select packaging/shipping requirements

Med 15 + år av CNC aluminum product processing experience, AOOM Technology guarantees competitive pricing without compromising quality. Visit aoomtech.com to request an instant quote or consult our engineering team.

Hur man hittar en pålitlig partner för högprecisionsblister

Hur man hittar en pålitlig partner för högprecisionsblister

Din guide till anpassningstjänster för precisionshårdvara CN

Din guide till anpassningstjänster för precisionshårdvara CN

Hur mycket kostar små partier CNC-bearbetning för anpassade

Hur mycket kostar små partier CNC-bearbetning för anpassade

En praktisk guide till liten sats CNC-bearbetning: Kostnad,

En praktisk guide till liten sats CNC-bearbetning: Kostnad,