CNC-bearbetning av högprecisionsdelar

I modern tillverkning, CNC high-precision parts processing is a critical technology for industries requiring tight tolerances and exceptional surface finishes. At AOOM, we specialize in delivering CNC machining solutions that meet the most demanding specifications for aerospace, medical, automotive, and industrial applications.

Vad är CNC High-Precision Delar Bearbetning?

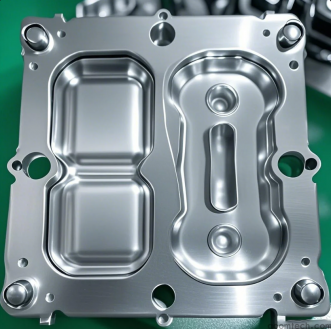

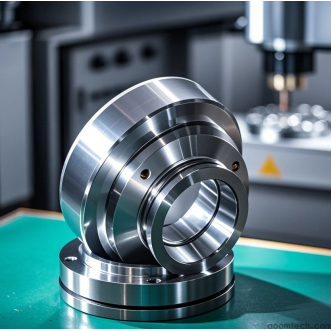

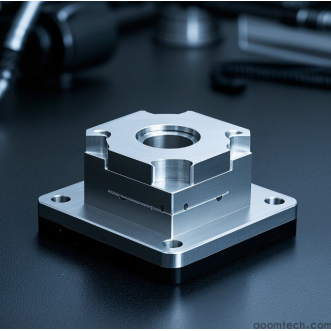

CNC högprecisionsdelar bearbetning avser användningen av datorstyrda maskiner för att tillverka komponenter med mikronivånoggrannhet. Denna process innefattar avancerad CNC-fräsning, svarvning och fleraxlig bearbetningsteknik, vilket säkerställer dimensionell konsistens och repeterbarhet även för komplexa geometrier.

Viktiga fördelar med vår CNC High-Precision Bearbetning

1. Toleranskontroll: Uppnå toleranser så täta som ± .005mm för kritiska applikationer.

2. Material Versatility: Process metals (aluminum, titanium, stainless steel), plastics, and composites.

3. Surface Finish: Deliver Ra .2μm or better for functional and aesthetic requirements.

4. Scalability: Support prototypes to high-volume production with consistent quality.

Branscher vi betjänar

Vår expertis spänner över:

Aerospace: Engine components, landing gear parts.

Medical: Surgical instruments, implantable devices.

Automotive: Fuel injection systems, transmission parts.

Electronics: Heat sinks, enclosures with EMI shielding.

Varför välja AOOM för CNC högprecisionsdelar?

1. Toppmodern utrustning: 5-axliga CNC-maskiner och CMM-inspektionssystem.

2. ISO 9001-Certified: Rigorous quality management at every stage.

3. Engineer Support: DFM feedback to optimize designs for manufacturability.

4. Fast Turnaround: Expedited services without compromising precision.

För CNC high-precision parts processing that combines accuracy, reliability, and cost-efficiency, contact AOOM to discuss your project requirements today.

Hur man hittar en pålitlig partner för högprecisionsblister

Hur man hittar en pålitlig partner för högprecisionsblister

Din guide till anpassningstjänster för precisionshårdvara CN

Din guide till anpassningstjänster för precisionshårdvara CN

Hur mycket kostar små partier CNC-bearbetning för anpassade

Hur mycket kostar små partier CNC-bearbetning för anpassade

En praktisk guide till liten sats CNC-bearbetning: Kostnad,

En praktisk guide till liten sats CNC-bearbetning: Kostnad,