CNC-formbearbetningsprocess

Förstå CNC-formbearbetning

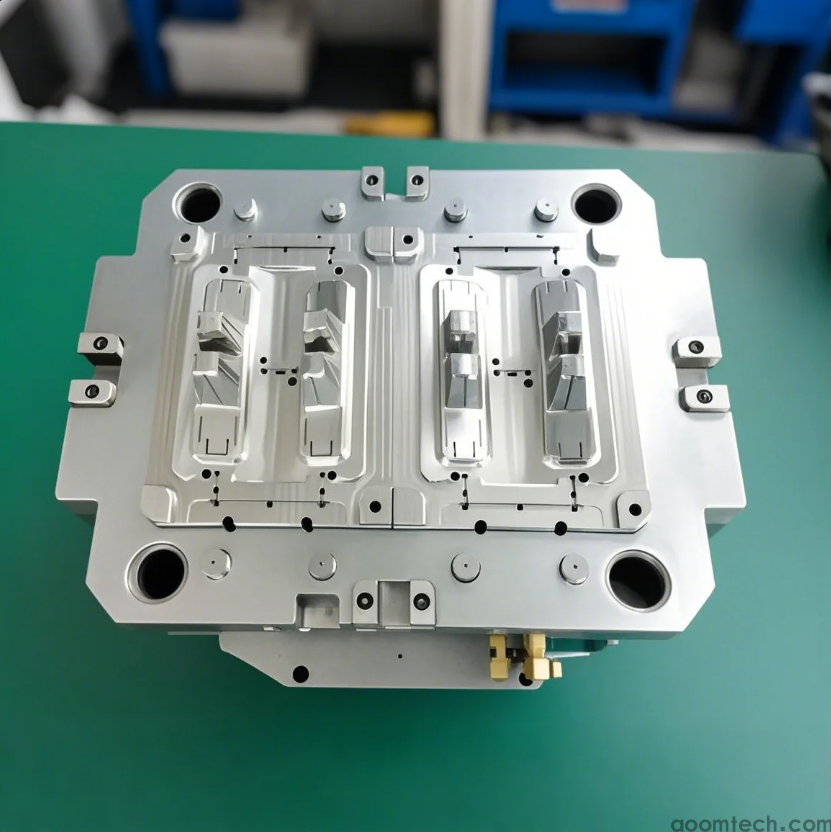

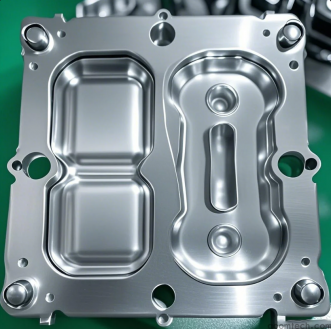

Den CNC mold machining process is a critical manufacturing technique that transforms raw materials into precision molds used across various industries. At AOOM, we specialize in delivering high-quality CNC machined molds with exceptional accuracy and surface finish.

Steg-för-steg-processfördelning

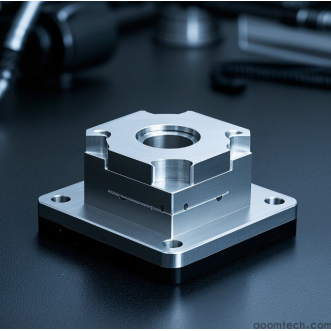

1. Design and Programming : Our engineers create 3D CAD models and generate precise CNC toolpaths using advanced CAM software.

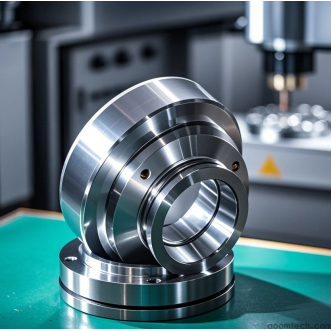

2. Material Selection : We carefully choose appropriate materials (typically tool steels or aluminum alloys) based on mold requirements.

3. Rough Machining : The initial shaping removes bulk material efficiently using high-power cutting tools.

4. Semi-Finishing : Intermediate operations bring the mold closer to final dimensions while maintaining proper tolerances.

5. Precision Finishing : The CNC machining process achieves final dimensions and surface quality through meticulous finishing passes.

6. Quality Inspection : We verify all critical dimensions using CMMs and other precision measuring instruments.

AOOMs tekniska fördelar

Vår anläggning har toppmoderna 5-axliga CNC-maskiner med komplexa geometrier med ± .01mm noggrannhet. Vi implementerar rigorösa processkontroller i hela CNC mold machining workflow to ensure consistent quality.

Tillämpningar över branscher

CNC-bearbetade formar från AOOM betjänar olika sektorer, inklusive fordons-, flyg-, medicintekniska produkter och konsumentelektronik. Vår expertis omfattar formsprutningar, formgjutningsformar och stansformar.

Varför välja AOOM för din mögeltillverkning

Med lång erfarenhet av CNC-mögelproduktion erbjuder AOOM konkurrenskraftiga ledtider, kostnadseffektiva lösningar och teknisk support under hela projektets livscykel. Besök vår hemsida på https://www.aoomtech.com / för att utforska våra möjligheter och begära en offert.

Hur man hittar en pålitlig partner för högprecisionsblister

Hur man hittar en pålitlig partner för högprecisionsblister

Din guide till anpassningstjänster för precisionshårdvara CN

Din guide till anpassningstjänster för precisionshårdvara CN

Hur mycket kostar små partier CNC-bearbetning för anpassade

Hur mycket kostar små partier CNC-bearbetning för anpassade

En praktisk guide till liten sats CNC-bearbetning: Kostnad,

En praktisk guide till liten sats CNC-bearbetning: Kostnad,