CNC Büyük Parça İşleme

Lider olarak CNC machining service provider, AOOM Technology specializes in precision manufacturing of large-scale components for industries ranging from aerospace to energy. This article explores the technical challenges and solutions in CNC large part machining .

CNC Büyük Parça İşleme Anlama

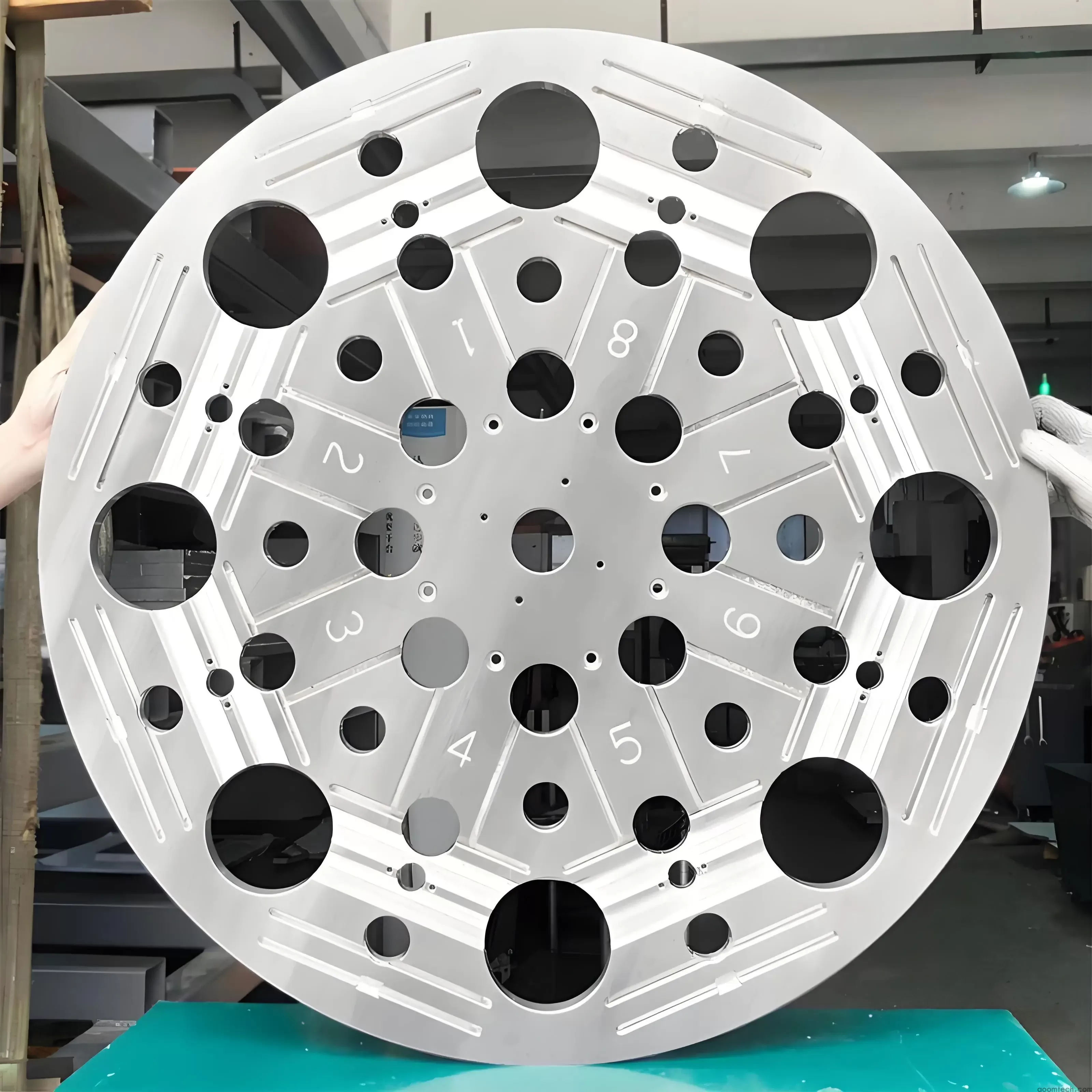

CNC büyük parça işleme Tipik olarak her boyutta 1 metreyi aşan, özel ekipman ve uzmanlık gerektiren bileşenlerin imalatını ifade eder. AOOM 'da, bu tür projelerin üstesinden gelmek için 5m × 3m × 2m' ye kadar iş zarflarına sahip kızak değirmenleri ve yatay işleme merkezleri kullanıyoruz.

Büyük Parça İşleme 'de Temel Zorluklar

1. Material Stability : Large metal parts are prone to thermal deformation during machining

2. Tool Path Optimization : Requires advanced CAM programming to maintain precision

3. Vibration Control : Our machines feature active damping systems for superior surface finish

AOOM 'un Teknik Avantajları

Tesisimizin özellikleri:

- 5-axis simultaneous machining capability for complex geometries

- On-machine inspection with laser trackers

- Temperature-controlled workshop (±1°C) for thermal stability

- Rigorous QA process including CMM verification

Sanayi Uygulamaları

Düzenli olarak şunları üretiyoruz:

- Aerospace structural components

- Energy sector turbine housings

- Industrial machinery bases and frames

- Transportation equipment large assemblies

Büyük Parça İhtiyaçlarınız İçin Neden AOOM 'u Seçmelisiniz?

15 + yıllık deneyim ile CNC machining , we offer:

1. One-stop solution from design to finished product

2. Tight tolerances (±.05mm achievable)

3. Material expertise including aluminum, steel, and titanium alloys

4. ISO 9001 certified quality management

Mühendislik ekibimizle iletişime geçin AOOM Technology to discuss your large-scale machining project requirements and receive a customized solution proposal.

Yüksek Hassasiyetli Küçük Toplu CNC İşleme Kılavuzunuz: Mali

Yüksek Hassasiyetli Küçük Toplu CNC İşleme Kılavuzunuz: Mali

Küçük Yüksek Hassasiyetli Parçalar CNC İşleme: Önemli Hususl

Küçük Yüksek Hassasiyetli Parçalar CNC İşleme: Önemli Hususl

Hangi Faktörler Yüksek Hızlı CNC İşleme Maliyetlerini Gerçek

Hangi Faktörler Yüksek Hızlı CNC İşleme Maliyetlerini Gerçek

CNC Hassas İşleme Ürünleri Ne İçin Kullanılabilir? Uygulamal

CNC Hassas İşleme Ürünleri Ne İçin Kullanılabilir? Uygulamal