CNC İşleme Probu: Kusursuz Üretim için Hassas Ölçüm

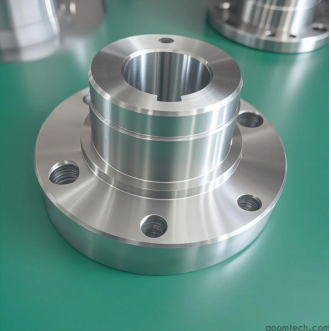

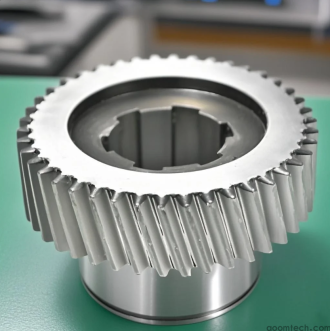

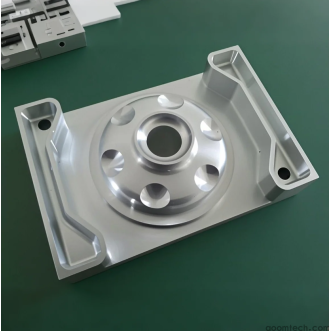

Modern CNC işlemede, mikron düzeyinde doğruluk elde etmek, gelişmiş makinelerden daha fazlasını gerektirir - aşağıdaki gibi güvenilir ölçüm araçları gerektirir: CNC machining probes. As a professional CNC service provider, AOOM Technology explains how this critical tool elevates your manufacturing quality.

CNC İşleme Probu nedir?

A CNC machining probe is a high-precision touch-trigger measurement device installed on CNC machines. It performs in-process inspection by contacting workpiece surfaces and transmitting positional data to the machine control system, enabling real-time compensation for tool wear or material variations.

Hassas Üretimde Temel Uygulamalar

1. Workpiece Alignment: Automatically establishes part zero points with .001mm repeatability

2. Tool Setting: Measures tool length/diameter offsets for optimal cutting parameters

3. In-Process Inspection: Verifies critical dimensions without removing parts

4. Batch Compensation: Adjusts machining programs based on first-article measurements

Neden AOOM 'un Prob Donanımlı CNC Hizmetlerini Seçmelisiniz?

bizim CNC machining centers integrate Renishaw probing systems to deliver:

• 30% reduction in setup time through automated alignment

• .005mm measurement accuracy for aerospace-grade parts

• Seamless integration with our ISO 9001-certified quality system

• Comprehensive probe data reporting for full traceability

AOOM Technology 'nin prob ile geliştirilmiş CNC çözümleri, prototip doğrulamasından yüksek hacimli üretime kadar parçalarınızın en dar toleransları karşılamasını sağlar. Contact our engineering team to discuss your project's specific measurement requirements.