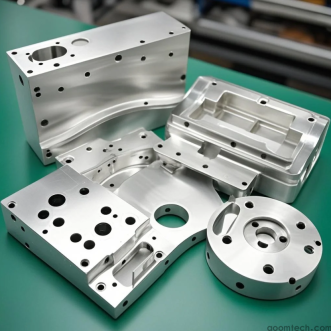

CNC bearbejdning Fitness udstyr dele

I fitnessbranchen kan præcision og holdbarhed ikke forhandles for udstyrskomponenter. CNC machining fitness equipment parts delivers unmatched accuracy and repeatability, making it the preferred manufacturing method for gym machinery manufacturers worldwide.

Hvorfor vælge CNC bearbejdning til fitness komponenter?

Fitnessudstyr står over for konstant stress fra gentagne bevægelser og tunge belastninger. CNC machining produces parts with tight tolerances (typically ±.005 inches) and superior surface finishes that withstand years of intensive use. Our 5-axis CNC machines at AOOM Technology can create complex geometries for:

- Justerbare remskivesystemer

- Vægt stak guider

- Barbell kraver

- Strukturkomponenter til løbebånd

- Modstandsmaskinforbindelser

Valg af materiale til optimal ydeevne

Vi maskiner fitness dele fra luftfart-kvalitet aluminium (6061-T6, 7075), rustfrit stål (304, 316) og ingeniørplast (Delrin, UHMWPE). Hvert materiale gennemgår streng test for at sikre:

- Korrosionsbestandighed fra svedeksponering

- Høje forhold mellem styrke og vægt

- Slidstyrke til bevægelige dele

- FDA-overholdelse af greb og kontaktoverflader

AOOMs kvalitetssikringsproces

Alle fitness equipment part undergoes dimensional verification with CMM (Coordinate Measuring Machines) and functional testing. Our ISO 9001-certified facility maintains traceability from raw material to finished product, ensuring compliance with international safety standards like EN 957 for gym equipment.

Med 15+ år med speciale i fitnessindustriens komponenter kombinerer AOOM Technology avancerede CNC-funktioner med dyb domæneviden for at levere dele, der overgår OEM-specifikationer. Anmod om et tilbud i dag gennem vores official website for CNC solutions that keep fitness equipment operating flawlessly.

CNC bearbejdning Fitness udstyr dele

CNC bearbejdning Fitness udstyr dele

CNC bearbejdning aluminiumsdele: nøgleovervejelser

CNC bearbejdning aluminiumsdele: nøgleovervejelser

CNC Copper Parts Processing: Sådan vælger du den rigtige pro

CNC Copper Parts Processing: Sådan vælger du den rigtige pro

Anbefalede producenter til CNC Precision Machining

Anbefalede producenter til CNC Precision Machining