Sådan vælger du den bedste CNC-bearbejdningsfabrik: En omfattende guide

Valg af højre CNC machining factory is critical for ensuring precision, efficiency, and cost-effectiveness in your manufacturing projects. This guide will help you evaluate key factors when comparing suppliers, with insights tailored to procurement managers, engineers, and business owners.

1. Teknisk kapacitet og udstyr

En topklasse CNC machining factory should possess advanced multi-axis machines (3/4/5-axis), high-precision measuring tools (CMMs), and the ability to handle diverse materials like aluminum, titanium, and engineering plastics. AOOM Technology maintains 20+ CNC centers with ±.005mm tolerances, specializing in complex aerospace and medical components.

2. Kvalitetscertificeringer og standarder

Prioriter fabrikker med ISO 9001: 2015, AS910D eller IATF 16949 certificeringer. Disse demonstrerer strenge kvalitetskontrolsystemer. Vores anlæg implementerer inspektionsprotokoller med fuld proces med dokumenteret sporbarhed for hvert parti.

3. Branchespecifik erfaring

Evaluer fabrikens portefølje i din sektor. AOOM har leveret CNC machining solutions for automotive (EV battery enclosures), robotics (harmonic drive components), and telecommunications (5G antenna housings), with proprietary tooling solutions that reduce cycle times by 30%.

4. Forsyningskæde og Lead Time pålidelighed

De bedste partnere tilbyder gennemsigtig produktionsplan ** ng og råmaterialelagerstyring. Vi opretholder strategiske partnerskaber med materialeleverandører for at sikre 15-dages standard ledetid med hurtige 7-dages muligheder for presserende projekter.

Hvorfor vælge AOOM teknologi?

• DFM-analyse inkluderet i alle tilbud

• 24/7 project management support

• IP-protected manufacturing processes

• Annual 5% cost reduction guarantee for long-term partners

Besøg aoomtech.com to request your free design-for-manufacturability assessment today.

CNC ikke-standard præcision bearbejdning tilpasning

CNC ikke-standard præcision bearbejdning tilpasning

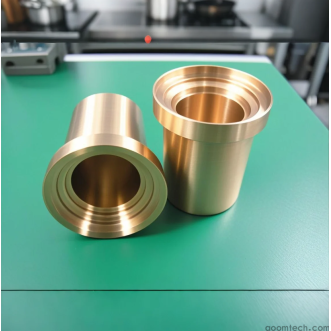

CNC bearbejdning ren kobber håndværk

CNC bearbejdning ren kobber håndværk

CNC bearbejdning metal belysning armaturer

CNC bearbejdning metal belysning armaturer

CNC præcision bearbejdning brugerdefinerede dele

CNC præcision bearbejdning brugerdefinerede dele