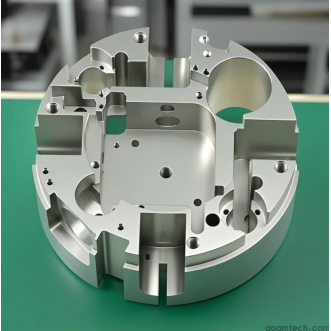

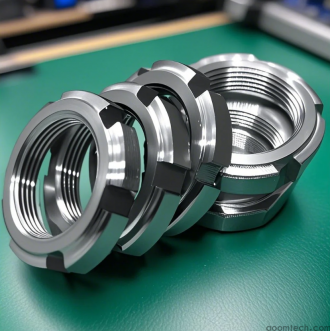

CNC ikke-standard metaldele bearbejdning

i moderne produktion, CNC non-standard metal parts machining has become a critical solution for industries requiring customized precision components. As a leading CNC machining service provider, AOOM Technology specializes in delivering high-accuracy, complex geometries for diverse industrial applications.

Hvad er CNC ikke-standard metal dele bearbejdning?

Denne proces indebærer brug af computerstyrede maskiner til at fremstille metalkomponenter, der ikke er i overensstemmelse med standardspecifikationer. I modsætning til masseproducerede dele kræver disse specialiseret programmering, værktøj og kvalitetskontrol for at imødekomme unikke designkrav.

De vigtigste fordele ved vores service

1. Precision Engineering: Our 5-axis CNC machines achieve tolerances within ±.01mm

2. Material Versatility: Aluminum, stainless steel, titanium, brass, and exotic alloys

3. Complex Geometry Handling: Capable of producing intricate shapes impossible with conventional methods

4. Rapid Prototyping: From CAD design to finished part in as little as 72 hours

Brancheapplikationer

Vores CNC non-standard parts serve critical functions in:

- Aerospace (engine components, mounting brackets)

- Medical (surgical instruments, implant prototypes)

- Automotive (custom fittings, performance parts)

- Robotics (specialized actuators, joint mechanisms)

Hvorfor vælge AOOM teknologi?

Med ISO 9001-certificerede faciliteter i Kina kombinerer vi avanceret tysk / japansk CNC-udstyr med proprietære kvalitetssikringsprotokoller. Vores ingeniører leverer DFM (Design til fremstilling) konsultationer for at optimere dine designs til omkostningseffektivitet uden at gå på kompromis med ydeevnen.

Kvalitetssikringsproces

Hver komponent gennemgår:

1. In-process dimensional verification

2. CMM (Coordinate Measuring Machine) inspection

3. Surface finish analysis

4. Material certification validation

For dit næste brugerdefinerede metaldele-projekt, besøg aoomtech.com to request a free engineering evaluation and competitive quotation.

CNC-aluminiumsproduktbehandlingstilbud

CNC-aluminiumsproduktbehandlingstilbud

CNC Titanium Alloy bearbejdningsproces Flow

CNC Titanium Alloy bearbejdningsproces Flow

Hvordan CNC bearbejdning processer store forme

Hvordan CNC bearbejdning processer store forme

CNC ikke-standard brugerdefineret bearbejdningsfabrikant

CNC ikke-standard brugerdefineret bearbejdningsfabrikant