CNC rustfrit stål Brugerdefineret bearbejdning: Præcisionsløsninger til dine projekter

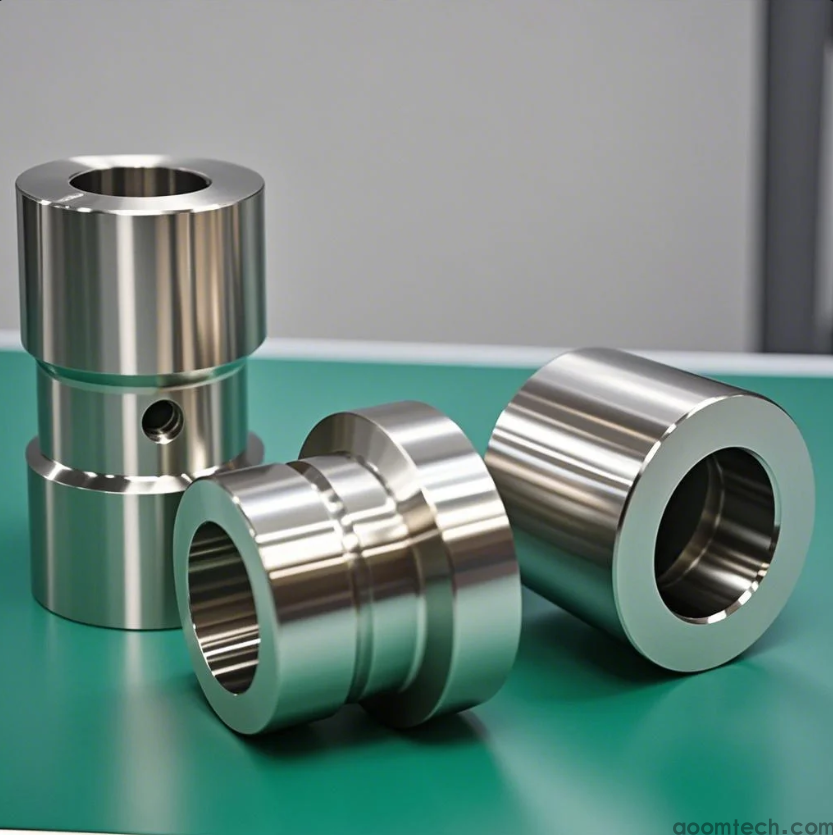

I dagens krævende industrilandskab, CNC stainless steel custom machining has become a cornerstone for manufacturers requiring durable, high-precision components. As a leading CNC machining service provider, AOOM Technology specializes in delivering tailored solutions that meet the strictest tolerances and surface finish requirements.

Hvorfor vælge CNC bearbejdning til rustfrit stål?

Rustfrit ståls ekstraordinære korrosionsbestandighed og mekaniske egenskaber gør det ideelt til luftfarts-, medicinske og bilindustrielle applikationer. Vores CNC stainless steel custom machining services leverage advanced 5-axis milling and turning centers to produce complex geometries with micron-level accuracy. The process begins with material selection (304, 316, or 17-4PH grades) and progresses through CAD/CAM programming to final quality inspection.

Nøglefordele ved vores tilpassede bearbejdningstjenester

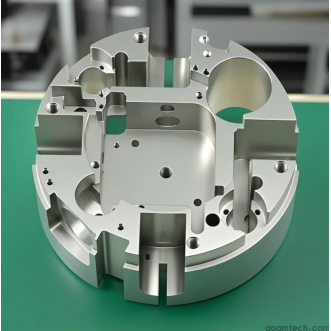

1. Precision Engineering: ±.005mm tolerance capability for critical dimensions

2. Surface Finish Options: From Ra .8μm mirror finishes to textured surfaces

3. Prototype to Production: Scalable solutions with fast turnaround times

4. Material Expertise: Machining all stainless steel grades without work hardening

Anvendelser på tværs af brancher

Vores CNC stainless steel custom machining capabilities serve diverse sectors:

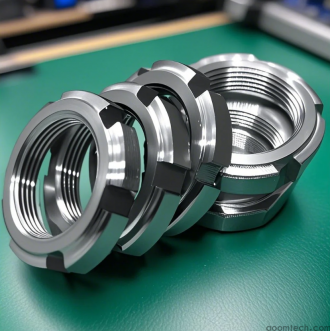

- Medical: Surgical instruments and implant components

- Food Processing: Hygienic fittings and machinery parts

- Energy: Valve bodies and pump components

- Automotive: Fuel system parts and turbocharger housings

Hos AOOM Technology kombinerer vi tyskfremstillet CNC-udstyr med ISO 9001-certificerede processer for at levere dele i rustfrit stål, der overstiger industristandarder. Vores ingeniørteam arbejder tæt sammen med kunderne for at optimere design til fremstillingsevne og omkostningseffektivitet uden at gå på kompromis med kvaliteten.

CNC-aluminiumsproduktbehandlingstilbud

CNC-aluminiumsproduktbehandlingstilbud

CNC Titanium Alloy bearbejdningsproces Flow

CNC Titanium Alloy bearbejdningsproces Flow

Hvordan CNC bearbejdning processer store forme

Hvordan CNC bearbejdning processer store forme

CNC ikke-standard brugerdefineret bearbejdningsfabrikant

CNC ikke-standard brugerdefineret bearbejdningsfabrikant