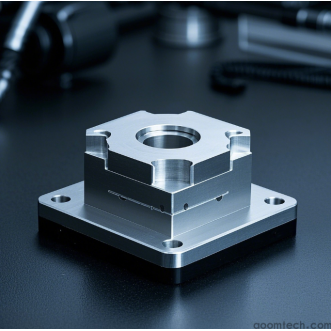

CNC højpræcisionsdelebehandling

i moderne produktion, CNC high-precision parts processing is a critical technology for industries requiring tight tolerances and exceptional surface finishes. At AOOM, we specialize in delivering CNC machining solutions that meet the most demanding specifications for aerospace, medical, automotive, and industrial applications.

Hvad er CNC High-Precision Parts Processing?

CNC højpræcisionsdelebehandling henviser til brugen af computerstyrede maskiner til at fremstille komponenter med mikronniveau nøjagtighed. Denne proces involverer avanceret CNC fræsning, drejning og multi-akse bearbejdningsteknikker, der sikrer dimensionel konsistens og gentagelighed selv for komplekse geometrier.

Nøglefordele ved vores CNC højpræcisionsbearbejdning

1. Tolerancekontrol: Opnå tolerancer så tæt som ± .005mm til kritiske applikationer.

2. Material Versatility: Process metals (aluminum, titanium, stainless steel), plastics, and composites.

3. Surface Finish: Deliver Ra .2μm or better for functional and aesthetic requirements.

4. Scalability: Support prototypes to high-volume production with consistent quality.

Industrier vi tjener

Vores ekspertise spænder over:

Aerospace: Engine components, landing gear parts.

Medical: Surgical instruments, implantable devices.

Automotive: Fuel injection systems, transmission parts.

Electronics: Heat sinks, enclosures with EMI shielding.

Hvorfor vælge AOOM til CNC High-Precision dele?

1. Modernt udstyr: 5-aksede CNC-maskiner og CMM-inspektionssystemer.

2. ISO 9001-Certified: Rigorous quality management at every stage.

3. Engineer Support: DFM feedback to optimize designs for manufacturability.

4. Fast Turnaround: Expedited services without compromising precision.

For CNC high-precision parts processing that combines accuracy, reliability, and cost-efficiency, contact AOOM to discuss your project requirements today.

CNC præcision bearbejdning leverandør

CNC præcision bearbejdning leverandør

Hvilken er en god CNC-præcisionsbearbejdningstjenesteudbyder

Hvilken er en god CNC-præcisionsbearbejdningstjenesteudbyder

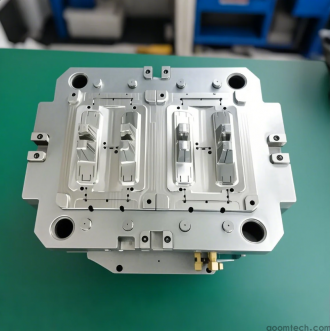

CNC Mold bearbejdningsproces

CNC Mold bearbejdningsproces

CNC højpræcisionsdelebehandling

CNC højpræcisionsdelebehandling