CNC Mold bearbejdningsproces

Forståelse af CNC Mold Machining

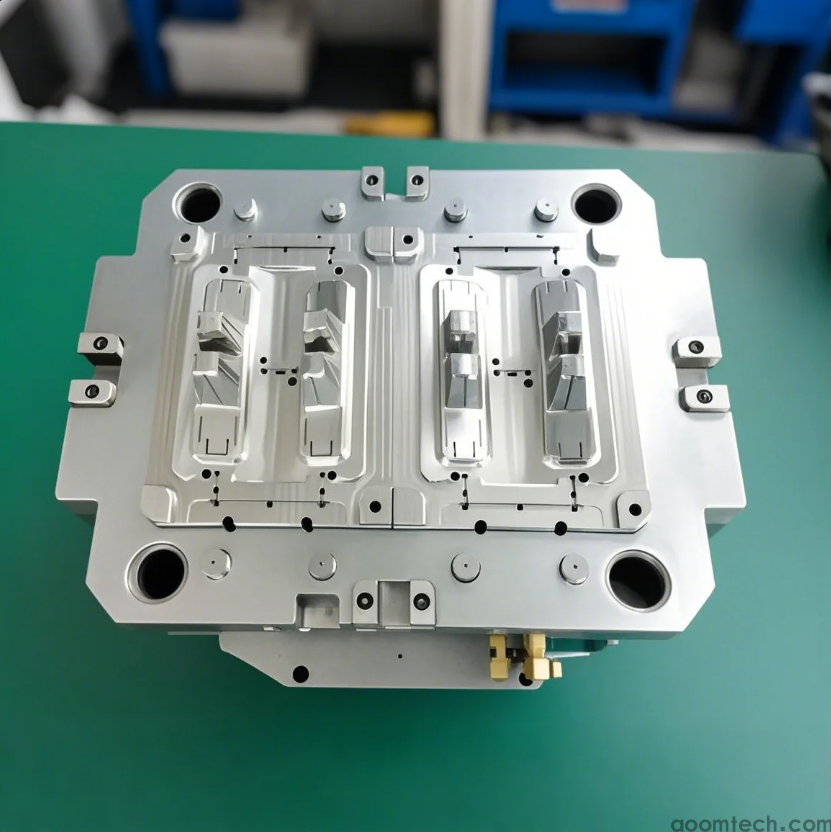

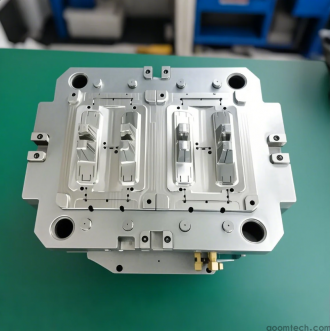

Den CNC mold machining process is a critical manufacturing technique that transforms raw materials into precision molds used across various industries. At AOOM, we specialize in delivering high-quality CNC machined molds with exceptional accuracy and surface finish.

Trin-for-trin procesopdeling

1. Design and Programming: Our engineers create 3D CAD models and generate precise CNC toolpaths using advanced CAM software.

2. Material Selection: We carefully choose appropriate materials (typically tool steels or aluminum alloys) based on mold requirements.

3. Rough Machining: The initial shaping removes bulk material efficiently using high-power cutting tools.

4. Semi-Finishing: Intermediate operations bring the mold closer to final dimensions while maintaining proper tolerances.

5. Precision Finishing: The CNC machining process achieves final dimensions and surface quality through meticulous finishing passes.

6. Quality Inspection: We verify all critical dimensions using CMMs and other precision measuring instruments.

AOOMs tekniske fordele

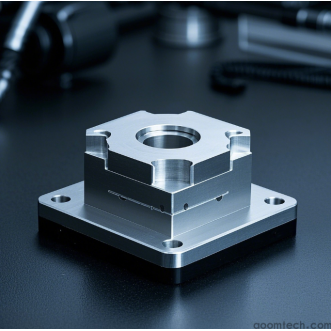

Vores anlæg har state-of-the-art 5-aksede CNC-maskiner, der er i stand til komplekse geometrier med ± .01 mm nøjagtighed. Vi implementerer strenge proceskontroller i hele CNC mold machining workflow to ensure consistent quality.

Anvendelser på tværs af brancher

CNC bearbejdede forme fra AOOM tjener forskellige sektorer, herunder bilindustrien, luftfartsindustrien, medicinsk udstyr og forbrugerelektronik. Vores ekspertise dækker sprøjtestøbe, støbeforme og stemplingstøbe.

Hvorfor vælge AOOM til din fremstilling af skimmel

Med stor erfaring inden for produktion af CNC-form tilbyder AOOM konkurrencedygtige ledetider, omkostningseffektive løsninger og teknisk support i hele dit projekts livscyklus. Besøg vores hjemmeside på https://www.aoomtech.com / at udforske vores muligheder og anmode om et tilbud.

CNC præcision bearbejdning leverandør

CNC præcision bearbejdning leverandør

Hvilken er en god CNC-præcisionsbearbejdningstjenesteudbyder

Hvilken er en god CNC-præcisionsbearbejdningstjenesteudbyder

CNC Mold bearbejdningsproces

CNC Mold bearbejdningsproces

CNC højpræcisionsdelebehandling

CNC højpræcisionsdelebehandling