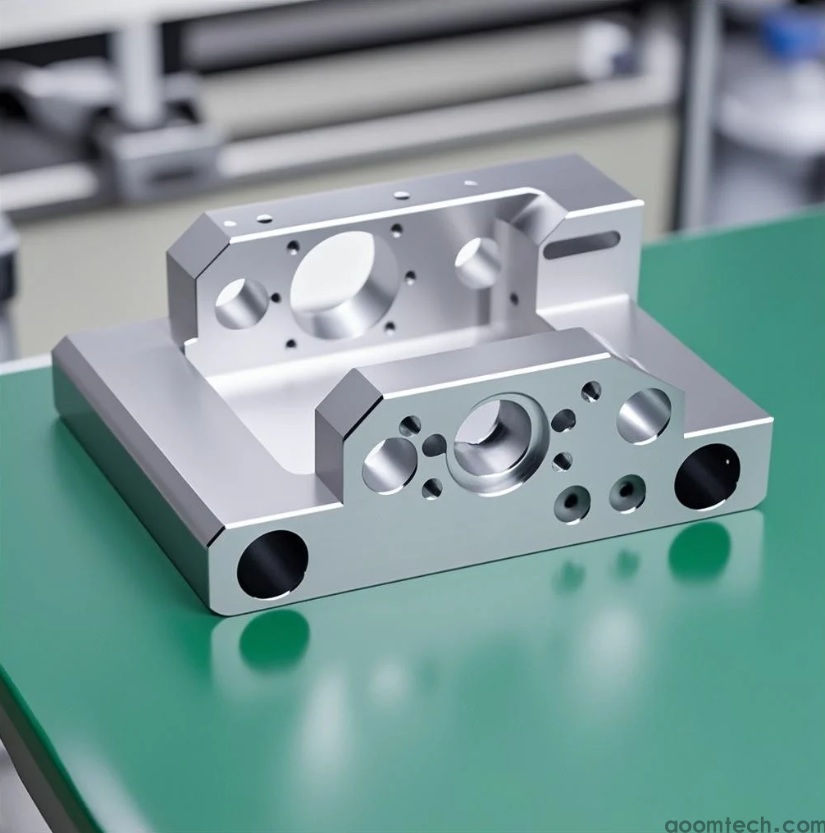

¿Qué precisión puede lograr el mecanizado CNC de 3 ejes?

Como proveedor profesional de servicios de mecanizado CNC, AOOM Technology entiende que la precisión es la piedra angular de la excelencia en la fabricación. Cuando los clientes preguntan por las capacidades de mecanizado CNC de 3 ejes, generalmente buscan claridad sobre las tolerancias alcanzables y los acabados de superficie para sus proyectos.

Comprensión de la precisión del mecanizado CNC de 3 ejes

Las máquinas CNC de 3 ejes estándar pueden mantener tolerancias de ±.005" (±.127mm) para la mayoría de los materiales, y algunas máquinas de alto rendimiento alcanzan ±.001" (±.025mm) en condiciones óptimas. La precisión real depende de múltiples factores, incluyendo la calibración de la máquina, la calidad de las herramientas, las características del material y la experiencia del operador.

Factores Clave Que Afectan La Precisión Del Mecanizado

1. Rigidez de la máquina: Nuestro equipo CNC alemán y japonés mantiene una estabilidad excepcional

2. Selección de herramientas: Usamos fresas de extremo de carburo de alta calidad de las principales marcas

3. Control de temperatura: El taller controlado por clima evita la expansión térmica

4. Sistemas de medición: Las máquinas CMM Mitutoyo verifican las dimensiones de las piezas

Las capacidades de precisión de AOOM

A través de nuestros procesos certificados ISO 9001, entregamos consistentemente:

- Tolerancia estándar: ±.005" (±.127mm)

- Tolerancia de alta precisión: ±.001" (±.025mm)

- Acabados de superficie hasta Ra .8μm (32μin)

Nuestro equipo de ingeniería puede recomendar estrategias óptimas de mecanizado para equilibrar los requisitos de precisión con la eficiencia de costos.

Aplicaciones del mecanizado de precisión de 3 ejes

Esta tecnología sirve a las industrias que requieren tolerancias estrictas:

• Componentes aeroespaciales

• Prototipos de dispositivos médicos

• Piezas automotrices

• Sistemas de automatización industrial

En AOOM Technology, combinamos equipos avanzados con décadas de experiencia en mecanizado para entregar componentes de precisión que cumplen con sus especificaciones exactas. Póngase en contacto con nuestro equipo de ingeniería para discutir los requisitos específicos de su proyecto.

Su guía para el mecanizado CNC de lotes pequeños de alta pre

Su guía para el mecanizado CNC de lotes pequeños de alta pre

Mecanizado CNC de piezas pequeñas de alta precisión: Conside

Mecanizado CNC de piezas pequeñas de alta precisión: Conside

¿Qué Factores Afectan Realmente Los Costos De Mecanizado CNC

¿Qué Factores Afectan Realmente Los Costos De Mecanizado CNC

¿Para Qué Se Pueden Usar Los Productos De Mecanizado De Prec

¿Para Qué Se Pueden Usar Los Productos De Mecanizado De Prec