アルミニウム部品のためのCNCバッチ加工プロセス

主役として CNC machining service provider, AOOM Technologies specializes in high-volume aluminum component manufacturing with precision and efficiency. This article will explore the critical aspects of CNC batch machining for aluminum parts, addressing the key concerns of procurement managers and engineers.

アルミニウムのためのCNCバッチ加工の理解

一括加工とは、CNC技術を用いて同一のアルミニウム部品を所定量生産することを指します。AOOMでは、100シリーズから700シリーズまでのアルミニウム合金を扱うことができる高度な3/4/5軸CNCマシンを採用し、寸法精度を±0.01 mm以内に確保しています。

主なプロセスステップ

1. Material Preparation: Selection of appropriate aluminum grade based on mechanical requirements

2. Fixture Design: Custom workholding solutions for batch consistency

3. Toolpath Optimization: CAM programming for maximum material removal rates

4. Quality Control: In-process inspection with CMM and surface roughness testers

私たちのバッチ加工サービスの利点

• Cost-effective production for quantities from 50-10,000+ units

• 15-30% faster cycle times through optimized tooling strategies

• Dedicated production cells for aluminum-specific machining

• ISO 9001-certified quality management system

業界アプリケーション

私たちのバッチ加工能力は以下を提供します:

- Aerospace: Structural components and housings

- Automotive: Engine parts and transmission elements

- Electronics: Heat sinks and enclosures

- Medical: Instrumentation components

12年以上のアルミニウム加工経験を持つAOOM Technologiesは、信頼性の高い製品を提供します。 CNC batch machining solutions that balance precision, speed, and cost-efficiency. Contact our engineering team today to discuss your specific project requirements.

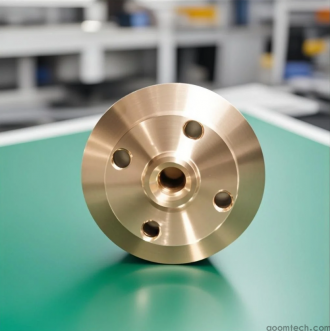

CNC加工真鍮プロセス

CNC加工真鍮プロセス

CNC精密機械部品加工:どの会社が専門ですか?

CNC精密機械部品加工:どの会社が専門ですか?

CNCボルト加工プロセス

CNCボルト加工プロセス

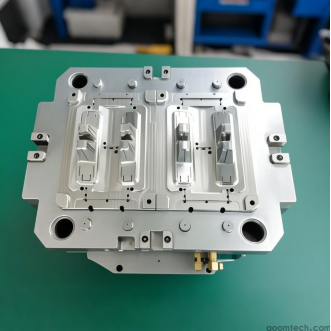

CNC金型加工:最適な結果を得るための重要な考慮事項

CNC金型加工:最適な結果を得るための重要な考慮事項