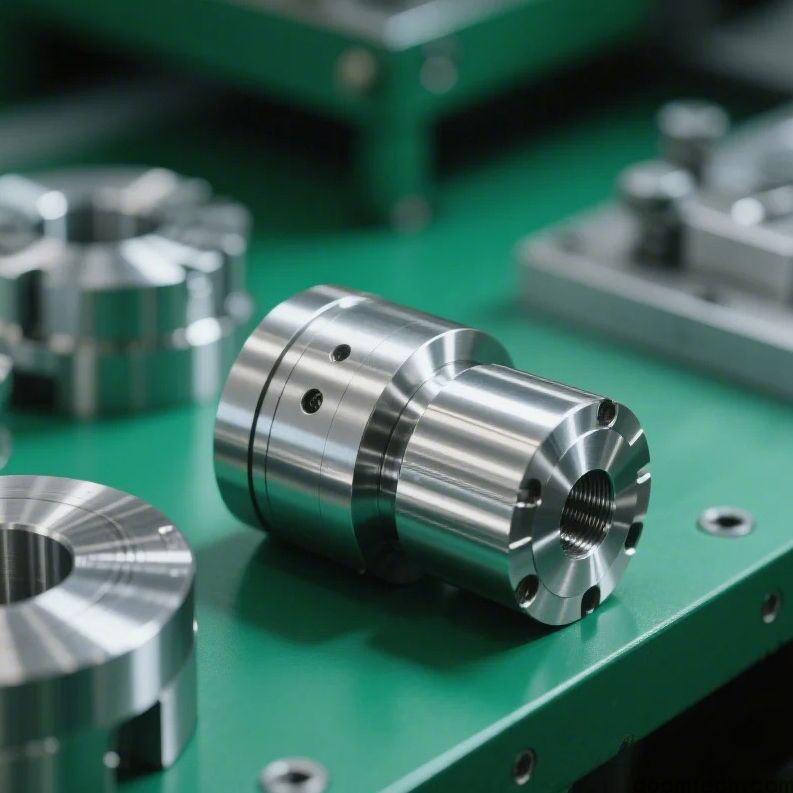

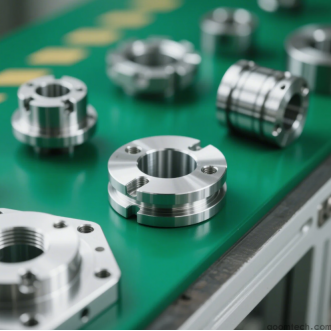

CNC加工による硬質材料の加工方法

CNC硬質材料加工の理解

チタン、硬化鋼、またはインコネルのような硬質材料の加工には、専門的な技術が必要です。 CNC machining techniques. At AOOM, we employ advanced tooling strategies and rigid machine setups to maintain precision while minimizing tool wear. The key challenges include heat generation, excessive tool pressure, and achieving desired surface finishes.

硬質材料CNC加工のための重要な技術

1. Tool selection: We use carbide or CBN tools with specialized coatings (TiAlN, diamond-like carbon) that withstand high temperatures.

2. Optimized cutting parameters: Reduced feed rates with higher spindle speeds prevent work hardening.

3. Rigid fixturing: Our 5-axis machines feature vibration-dampening systems for stability during heavy cuts.

4. Coolant management: Through-tool coolant delivery prevents thermal deformation of workpieces.

AOOMの硬質材料加工能力

私たちの施設の特徴:

• 40+ CNC mills/lathes with 15+ dedicated to hard material processing

• In-house tool grinding for custom geometries

• CMM inspection to ensure ±.005mm tolerances

• Post-processing options including heat treatment and precision grinding

業界アプリケーション

私たちは、製品の性能と寿命にとって硬質材料の加工が重要な航空宇宙(タービン部品)、医療(外科インプラント)、自動車(パフォーマンスドライブトレイン)産業にサービスを提供しています。

CNC部品加工メーカー

CNC部品加工メーカー

何の製品をCNCマシンで加工できますか?

何の製品をCNCマシンで加工できますか?

CNCベリリウム銅加工プロセス

CNCベリリウム銅加工プロセス

エンジン部品のCNC加工プロセス

エンジン部品のCNC加工プロセス