精密製造のためのCNC旋盤カスタマイズサービス

現代の製造業では、 CNC turning customization has become a cornerstone for industries requiring high-precision components. As a trusted provider at AOOM Technologies, we specialize in delivering tailored solutions that meet stringent quality standards while optimizing production efficiency.

CNC旋盤カスタマイズとは何ですか?

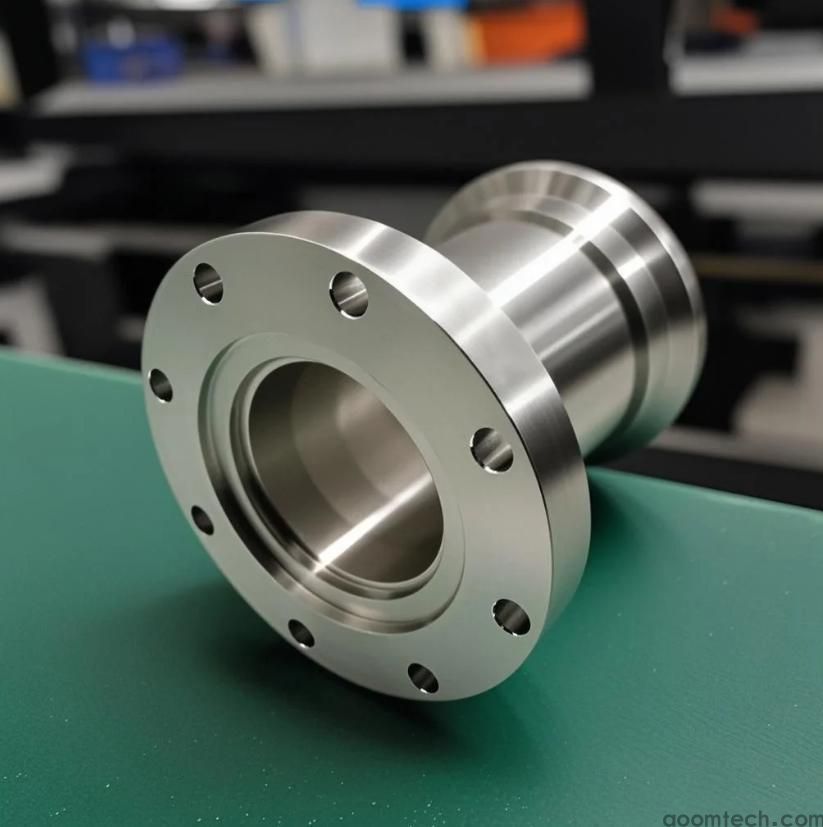

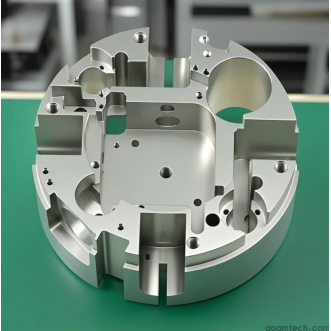

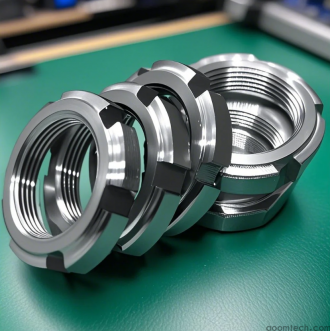

CNC旋盤のカスタマイズ 切削工具が材料を除去しながらワークピースを回転させて精密部品を作成する過程を指します。この方法は、狭い公差(±0.0 0 5 mm以下)を持つ円筒形または円錐形を製造するのに最適です。AOOMの高度なCNC旋盤は、アルミニウム合金からチタンまでの材料において、スレッド、溝、テーパー形状などの複雑なジオメトリを可能にする多軸操作をサポートしています。

カスタムCNCターニングにAOOMを選択する主な利点

1. Material Expertise: We machine over 50+ metals/plastics, including challenging materials like Inconel and PEEK.

2. Precision Guarantee: ISO 9001-certified processes ensure dimensional accuracy up to IT6 grade.

3. Rapid Prototyping: 3-5 day lead times for prototype batches through our dedicated quick-turn service.

4. Surface Finish Options: From Ra .8μm mirror finishes to powder coating/anodizing.

カスタムターニングソリューションを提供する産業

• Aerospace: Flight-critical components like hydraulic fittings

• Medical: FDA-compliant surgical instrument parts

• Automotive: High-volume fuel injection components

• Energy: Corrosion-resistant valve bodies for offshore applications

エンドツーエンドのカスタマイズワークフロー

1. Design Consultation: DFM analysis using SolidWorks/Creo software

2. Material Selection: Technical guidance on optimal grade selection

3. Process Planning: Toolpath optimization for minimal material waste

4. Quality Validation: CMM inspection with comprehensive reports

AOOM Technologiesでは、ドイツで設計されたDMG MORI機械と15年以上の加工技術を組み合わせて、 CNC turning customization that exceeds expectations. Request your free project evaluation today to experience precision manufacturing redefined.

CNCアルミニウム製品の加工見積もり

CNCアルミニウム製品の加工見積もり

CNCチタン合金の加工プロセスの流れ

CNCチタン合金の加工プロセスの流れ

CNC加工による大型金型の加工方法

CNC加工による大型金型の加工方法

CNC非標準カスタム加工メーカー

CNC非標準カスタム加工メーカー