CNC 볼트 가공 프로세스

정밀 제조에서 CNC bolt machining process stands as a critical operation for industries requiring high-tolerance fasteners. As a leading CNC machining service provider, AOOM Technology delivers exceptional bolt manufacturing solutions tailored to aerospace, automotive, and industrial applications.

CNC 볼트 가공 이해

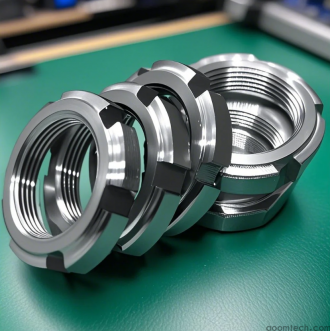

CNC bolt machining process involves computer-controlled lathes or milling machines transforming raw metal bars into precision bolts through sequential operations including turning, threading, head forming, and surface finishing. Our 5-axis CNC machines achieve ±.005mm tolerances, ensuring perfect thread engagement and load distribution.

CNC 볼트 생산의 주요 이점

1. Material Versatility: We machine bolts from stainless steel, titanium, aluminum, and exotic alloys

2. Thread Precision: ACME, UN, metric, and custom thread profiles with certified accuracy

3. Surface Treatments: Optional plating, anodizing, or passivation for corrosion resistance

4. Batch Flexibility: From prototype quantities to 100,000+ production runs

기술 사양

우리 CNC bolt machining process accommodates:

• Diameter range: M1.6 to M64

• Length-to-diameter ratios up to 12:1

• Head types: Hex, socket, flange, and custom designs

• Compliance with ISO 898, ASME B18.2, and DIN standards

AOOM 기술을 선택하는 이유는 무엇입니까?

15년 이상의 CNC 가공 전문 지식을 바탕으로 엄격한 품질 관리(100% 나사산 게이지 포함)와 고급 스위스형 선반을 결합하여 완벽한 기계적 특성을 가진 볼트를 제공합니다. 당사의 엔지니어는 절삭 속도에서 공구 경로에 이르기까지 모든 가공 파라미터를 최적화하여 최대의 인장 강도 및 피로 저항성을 보장합니다.

무료 프로젝트 검토 요청 www.aoomtech.com to experience precision bolt manufacturing that eliminates assembly issues and reduces total fastener costs.

CNC 비표준 맞춤 가공 제조업체

CNC 비표준 맞춤 가공 제조업체

CNC 부품 가공은 어떤 회사를 선택해야 하나요?

CNC 부품 가공은 어떤 회사를 선택해야 하나요?

CNC 부품 가공 및 제조 프로세스

CNC 부품 가공 및 제조 프로세스

CNC 제품 처리 권장 제조업체

CNC 제품 처리 권장 제조업체