Aliran Proses Pemesinan Besi Tuang CNC

Memahami Pemesinan Besi Tuang CNC

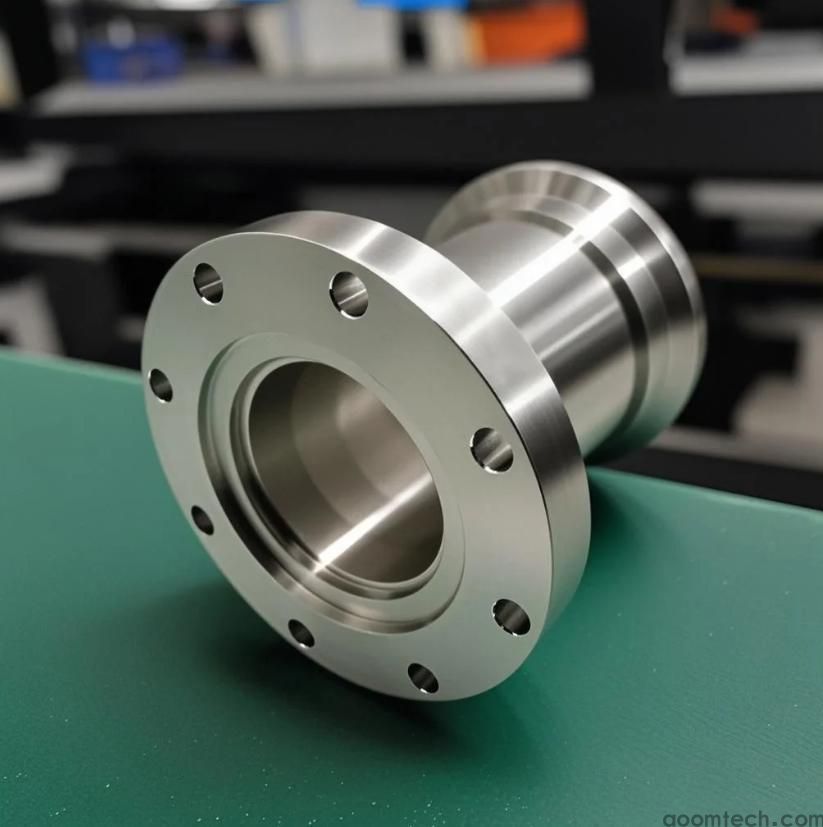

Pemesinan besi tuang CNC ialah proses pembuatan khusus yang memerlukan kawalan dan kepakaran yang tepat. Sebagai bahan berkekuatan tinggi, tahan haus, besi tuang memberikan cabaran dan peluang unik dalam pemesinan CNC. Di AOOM Technologies, kami telah menyempurnakan proses untuk memberikan hasil yang luar biasa untuk industri yang terdiri daripada automotif kepada jentera berat.

Langkah Utama dalam Proses Pemesinan Besi Tuang CNC

Yang lengkap CNC machining process for cast iron involves several critical stages:

1. Material Selection: Choosing the right grade of cast iron (gray, ductile, or malleable) based on application requirements.

2. Workpiece Preparation: Proper fixturing and alignment to ensure stability during machining.

3. Tool Selection: Using carbide or CBN tools specifically designed for cast iron's abrasive nature.

4. Machining Parameters: Optimizing cutting speeds, feed rates, and depth of cut to prevent tool wear.

5. Coolant Application: Implementing appropriate cooling strategies to manage heat and extend tool life.

Pertimbangan Teknikal untuk Keputusan Optimum

Berjaya cast iron CNC machining requires attention to several technical factors:

- Vibration Control: Cast iron's damping properties help, but proper machine rigidity is still essential.

- Chip Management: Cast iron produces short, brittle chips that require efficient removal systems.

- Surface Finish: Achieving desired surface quality through proper tool path strategies.

- Dimensional Accuracy: Accounting for potential material movement during machining.

Mengapa Memilih Teknologi AOOM untuk Projek Besi Tuang CNC Anda

Kepakaran kami dalam pemesinan besi tuang CNC membezakan kami:

- Advanced Equipment: State-of-the-art CNC machines capable of handling cast iron's demands.

- Process Optimization: Years of experience fine-tuning parameters for different cast iron grades.

- Quality Assurance: Rigorous inspection protocols to ensure every part meets specifications.

- Turnkey Solutions: From design assistance to final finishing, we handle all aspects of production.

Untuk projek pemesinan besi tuang anda yang seterusnya, percayai Teknologi AOOM untuk memberikan ketepatan, kebolehpercayaan dan nilai yang luar biasa. Lawati tapak web kami di https://www.aoomtech.com / untuk mengetahui lebih lanjut tentang keupayaan kami.

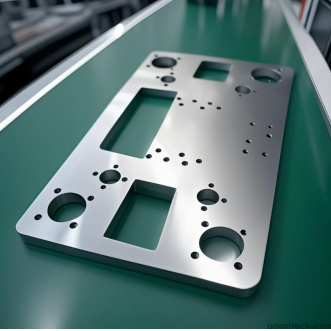

Pemprosesan Batch CNC Bahagian Aluminium: Pertimbangan Utama

Pemprosesan Batch CNC Bahagian Aluminium: Pertimbangan Utama

Teknologi Pemprosesan Keluli Plastik CNC

Teknologi Pemprosesan Keluli Plastik CNC

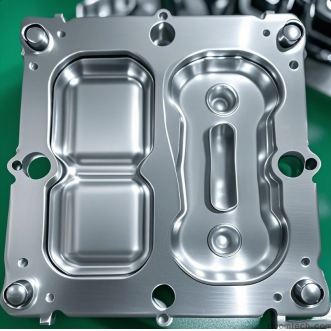

Pemesinan Acuan CNC: Cara Memilih Pembekal yang Betul

Pemesinan Acuan CNC: Cara Memilih Pembekal yang Betul

Pengeluar Pemprosesan Perkakasan Profesional CNC

Pengeluar Pemprosesan Perkakasan Profesional CNC