CNC Mold Processing: Key Considerations for Optimal Results

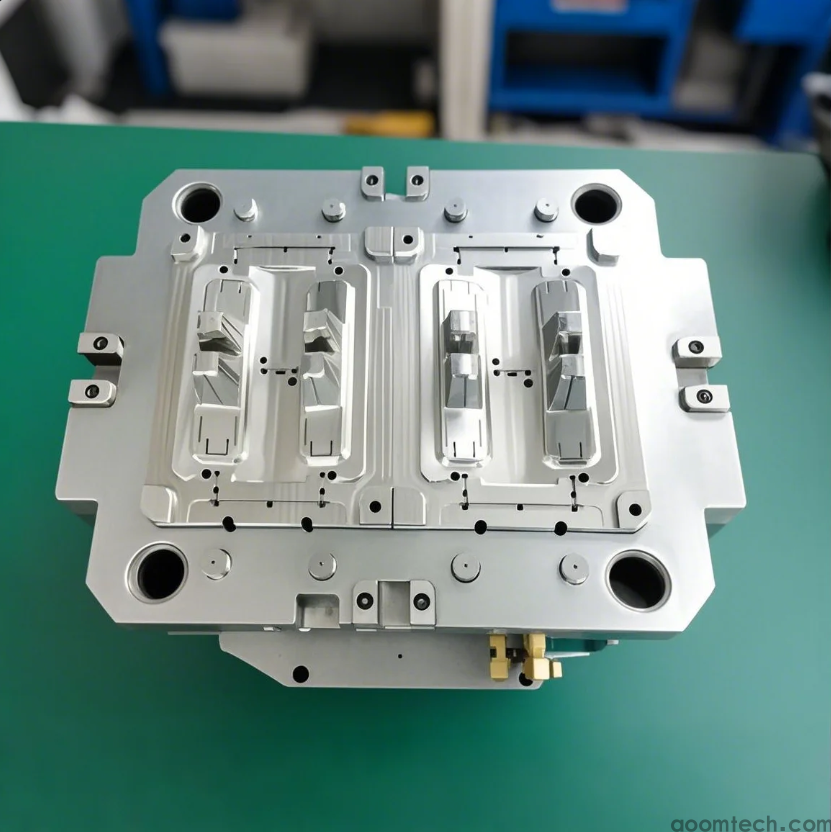

As a leading CNC machining service provider, AOOM Technology specializes in precision CNC mold processing for various industries. This article explores critical factors to ensure high-quality mold production through CNC technology.

Material Selection for CNC Mold Processing

The choice of material significantly impacts mold performance and longevity. Common materials include tool steels (P20, H13), aluminum alloys, and carbide. Considerations must include hardness, thermal stability, and machinability. Our engineers at AOOM carefully evaluate each project's requirements to recommend the optimal material.

Precision and Tolerance Requirements

CNC mold processing demands exceptional precision, often requiring tolerances within ±.01mm. We utilize advanced 5-axis CNC machines and rigorous quality control processes to meet these exacting standards. Proper machine calibration and tool compensation are essential for maintaining consistency.

Surface Finish Considerations

Mold surface quality directly affects the final product. Factors like tool path strategy, cutting parameters, and post-processing (polishing, EDM) must be carefully planned. AOOM's technicians optimize these parameters based on mold design and application requirements.

Cooling System Design Integration

Effective cooling channels are crucial for production efficiency. During CNC machining, cooling channel placement must maintain structural integrity while ensuring optimal thermal management. Our team uses advanced simulation software to verify designs before machining.

Preventive Maintenance for Longevity

Regular maintenance of CNC equipment and proper mold storage are vital for consistent performance. AOOM implements strict maintenance protocols and provides clients with detailed care instructions for extended mold life.

At AOOM Technology, we combine technical expertise with state-of-the-art CNC equipment to deliver superior mold processing solutions. Visit our website at https://www.aoomtech.com/ to learn more about our comprehensive CNC machining services.

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How Much Does Small Batch CNC

How Much Does Small Batch CNC

How to Prevent Deformation in

How to Prevent Deformation in