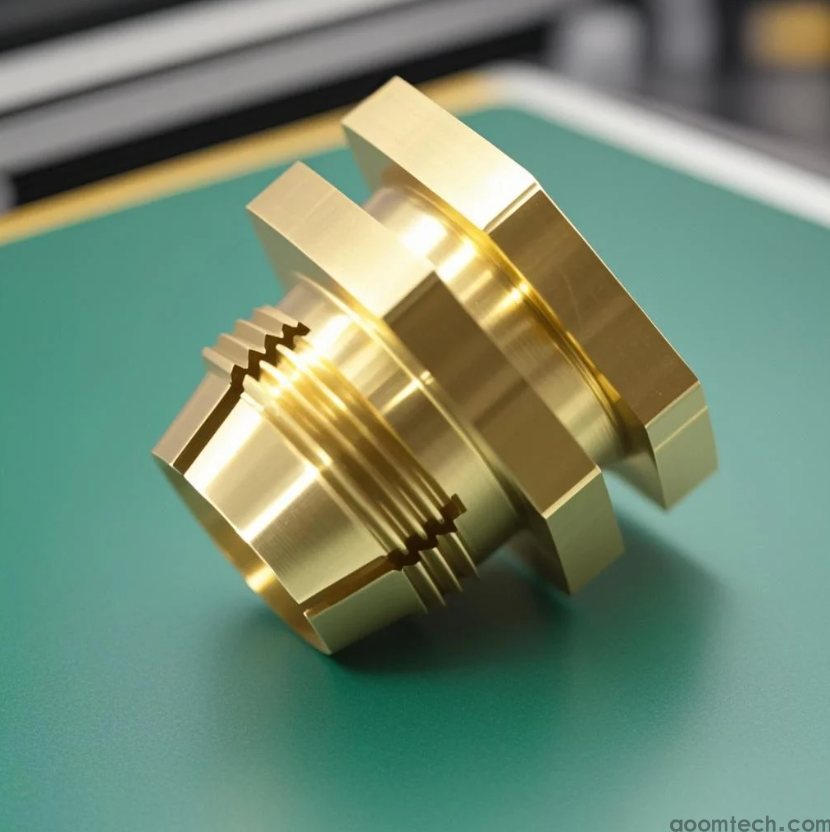

Precision Craft CNC Machining, Metal Craft CNC Machining

Are you tired of your high-end product designs being let down by manufacturing that just isn't precise enough? 😥 The surface is rough, the details are blurry, and it totally loses the artistic feeling you were going for. This is a common pain point for many designers and procurement managers. When it comes to creating top-tier crafts or luxury goods, precision and material choice are everything. Let's talk about how CNC machining solves this.

What Exactly is Precision Craft CNC Machining?

At its core, it's about making art with machines. Think of it as a super-accurate digital sculptor. We're talking about details finer than a human hair. This isn't your average machining; it's a dedicated process for pieces where every micron matters. While the goal is perfection, it's worth mentioning that achieving sub-micron level consistency on extremely complex organic shapes can still be a challenge that pushes the limits of current technology.

Why is Metal a Go-To Material for High-End Crafts?

Metal just has a presence that plastic can't match. It feels substantial, valuable, and timeless. But it's not just about looks:

• Durability: A metal craft can last for generations, no joke.

• Premium Finish: You can polish it to a mirror shine, or brush it for a sophisticated matte look. The options are vast.

• Intricate Details: CNC machines can carve incredibly fine patterns into metals like brass or aluminum, capturing the soul of your design.

Having said that, working with metal is harder on the tools and usually costs more than other materials, which is a key factor in your cost planning.

What's the Real Workflow Like? From File to Finished Piece

It's a more involved process than people might think. I often use a 5-step approach in my projects:

1. 3D Model Finalization: This is the blueprint. Any error here gets carved in metal, literally.

2. Programming the CNC Path: The technician translates your model into a language the machine understands. This is where their expertise makes or breaks the part.

3. Material Selection & Setup: Choosing the right metal stock and securing it perfectly in the machine.

4. The Machining Process: This is where the magic happens, with cutting tools shaping the block. Multiple tools and steps are often involved.

5. Post-Processing: This is the secret sauce. Deburring, polishing, and maybe even plating or anodizing for color.

This whole journey, from a digital file to a physical object you can hold, still amazes me. It perhaps suggests that we're blending the worlds of traditional craftsmanship and digital precision.

How to Spot a Supplier That Can Actually Deliver Quality

Not all machine shops are created equal. Here's what I look for:

• Ask for a Portfolio: Don't just take their word for it. Demand to see photos of previous craft projects. Look at the finish and detail.

• Inquire About Their Equipment: Older machines might not hold the tolerances you need for a true "level one" craft.

• Communication is Key: Do they understand your aesthetic goals, or are they just talking about specs? A good partner gets both.

But honestly, the specific mechanism for how some shops consistently achieve a "hand-finished" look with CNC is something I'm still curious about—it seems to be a closely guarded secret.

A Little Secret: The Power of Prototyping

Before you commit to a full production run, especially for a complex piece, get a prototype made. It's an upfront cost that can save you a fortune later. You can test the feel, the weight, and the overall look. It's your chance to catch issues before they become expensive mistakes. This one step has saved my projects more times than I can count. 😌

Ultimately, finding the right partner for precision metal crafts is about shared standards. It's not just a purchase order; it's a collaboration to bring something exceptional into the world.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C