How to Choose a Supplier for CNC Machining Copper Parts

Finding a workshop that says they can machine copper is easy. But finding the *right* partner who truly understands the quirks of copper and can deliver consistent, precision results? That's where the real challenge begins. 😓 If you're a procurement manager or an engineer tired of dealing with surface scratches, poor tolerances, or unreliable delivery on your copper components, you're asking the perfect question. Let's break down this selection process, step by step.

First Things First: Why Is Machining Copper So Tricky?

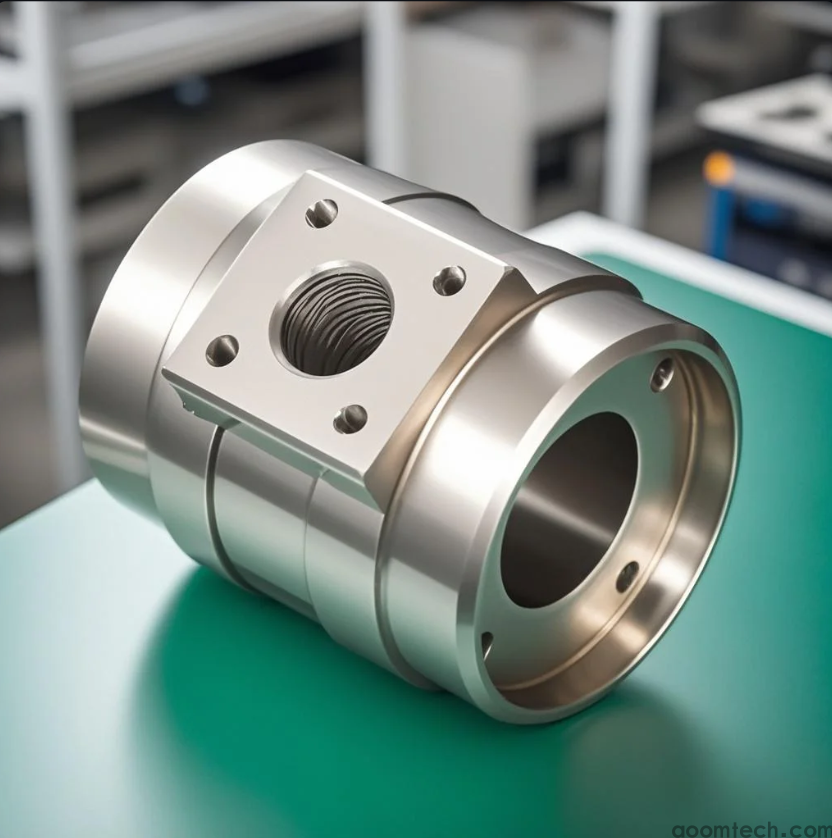

Before we dive into choosing, let's understand the "why." Copper and its alloys (like brass and bronze) are wonderful materials—great conductivity, corrosion resistance, and machinability. However, they can be soft and gummy, which sounds good but can lead to built-up edge on tools, poor surface finish if not handled correctly, and challenges in holding tight tolerances. A supplier who treats copper like steel is a red flag. 🚩

Step 1: Look Beyond the Machine List (Evaluate Their Expertise)

Many suppliers will list their CNC machines. That's basic. You need to dig deeper:

• Ask about *specific* experience with copper alloys: "How many projects have you done with C11000 electrolytic copper or C36000 brass?" Real experience matters.

• Inquire about tooling and parameters: Do they use specialized tool geometries or coatings (like diamond-like carbon) for non-ferrous metals? Their answer perhaps hints at their level of sophistication.

• Request case studies or samples: Seeing is believing. A confident supplier can show you finished parts.

My take: I often see buyers over-index on machine brand. But a seasoned operator on a older machine can outdo a novice on the latest model when it comes to finicky materials like copper.

Step 2: Scrutinize Their Quality Control Process

Precision is non-negotiable. How do they guarantee it?

• First-article inspection (FAI): Do they have a formal process? Will they provide you with inspection reports?

• In-process checks: For longer runs, how do they ensure part 10 is identical to part 1?

• Measurement equipment: Do they have capable tools (like micrometers, CMMs, surface profilometers) to verify the specs *you* care about?

Here's a pro tip: Ask them, "What's the most common quality issue you encounter with copper parts, and how do you prevent it?" Their response will tell you volumes about their problem-solving mindset.

Step 3: Communication and Service - The Make or Break

This might be the most important step. A perfect part delivered late is useless. A small issue that can't be communicated clearly becomes a big problem.

• Responsiveness: Do they answer technical questions clearly and promptly?

• Transparency on challenges: If there's a design for manufacturability (DFM) issue, will they speak up early, or just quote and hope for the best?

• Willingness to collaborate: Are they a true partner for prototyping and refining the design?

Personal viewpoint: I'd choose a slightly more expensive supplier with flawless communication over a cheaper, silent one any day. The hidden costs of miscommunication are enormous. but speaking of which..., you need to balance cost with all these factors.

Step 4: Don't Make Price the First Question

We all have budgets. But leading with "how much per piece?" puts you in a commodity mindset. First, establish they are technically capable and a good fit (Steps 1-3). Then, discuss pricing. A detailed RFQ with clear drawings, material specs, quantities, and tolerance requirements will get you comparable quotes. Be wary of the quote that's drastically lower than others—it often means a compromise somewhere.

So, what now? You've got a framework. The next move is to start conversations with potential partners. When you're ready to discuss your specific copper part project with a supplier who gets it, the clearest path is to reach out directly. 👉 Have your drawings ready and start a conversation with our technical team today. We're here to help you navigate from prototype to production, smoothly.

How to Choose a Supplier for C

How to Choose a Supplier for C

Small Batch CNC Machining Part

Small Batch CNC Machining Part

Small Batch Multi-Variety CNC

Small Batch Multi-Variety CNC

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi