Small Batch Multi-Variety CNC Machining Rapid Prototyping Service

Ever feel stuck in a loop? You need just 50 parts, maybe 5 different designs, and you need them yesterday to test the market or fix a design flaw. But every quote you get seems built for orders of 5,000, not 50. The setup costs are sky-high, the lead times are endless, and the whole process feels... rigid. 😫 Sound familiar? If you're a procurement manager or engineer wrestling with the "small batch paradox" – high need, low "traditional" viability – you're not alone. This article cuts straight to the chase: what does a true small batch, multi-variety CNC rapid prototyping service look like, and how can it actually work for you?

What Exactly Is This Service, and Why Is It So Tricky?

Let's break it down simply. A proper service for small batch multi-variety CNC machining isn't just a big factory reluctantly taking a small job. It's a specialized workflow designed from the ground up for agility.

The core idea is this: It combines the precision of CNC machining with the flexibility typically found in a workshop, but at a scale and speed that makes sense for pre-production. The "tricky" part for most shops is economics. Traditional CNC runs thrive on repetition. Changing a design means stopping, re-programming, changing tools – all of which costs time and money. For one part, that cost is huge. For 50 different parts? It can seem impossible.

But here's the thing: A service built for this challenge uses different strategies – like advanced CAM programming to group similar operations, quick-change tooling systems, and a mindset that values quick-turn adaptability over massive volume throughput. It's a different beast.

How Can a Supplier Actually Make This Cost-Effective? 🤔

This is the million-dollar question, right? We hear it all the time. If you're thinking, "Sure, it sounds great, but the price must be astronomical," I get it. The old rule was: low volume = high price per part.

However, the game has changed. Smart suppliers now leverage a few key approaches:

- Digital-First Workflow: From your 3D model to machine code, the process is highly automated. This slashes the engineering quote time from days to hours.

- Machine & Material Agility: They use machines that can handle multiple operations in one setup (like 5-axis or mill-turn centers) and keep a wide range of common prototype materials (6061 aluminum, Delrin, PEEK, 304 Stainless) in stock, avoiding special order delays.

- Pricing Transparency: You should see a clear breakdown: machine time, material, and a reasonable setup fee. No hidden "small order" penalties.

But speaking of which..., true cost-effectiveness isn't just about the unit price on a quote. It's about speed-to-market and risk reduction. Getting functional prototypes in hand fast means you can test, iterate, and fail quickly (and cheaply) before committing to mass production. That saved time and avoided error is where the real ROI hides.

What Should You Look for to Ensure Quality? 🧐

With multiple designs flying around, how do you prevent a mix-up or a quality slip? This is where the supplier's system proves its worth. You're not just buying machining; you're buying process control.

My personal view? Don't just ask for a quality certificate. Ask about their job management process. A reliable partner will have:

- Digital Travelers: Each batch, even of 10 pieces, has its own digital job card that follows it through every step, ensuring the right program and specs are used.

- First-Article Inspection (FAI) as Standard: For every new design variant, the first piece off the machine should be fully measured and reported to you before the rest are run. This catches issues early.

- Clear Communication Channels: You should have a direct line to the engineer or project manager handling your job, not just a general sales inbox. Quick clarifications prevent big mistakes.

This structured yet flexible approach to quality might suggest a supplier who is serious about serving the prototype and low-volume niche, not just tolerating it.

From Prototype to Production – Is the Path Smooth?

A huge worry is getting stuck with a "prototype-only" vendor. You perfect your design with them, then have to scramble to find a mass-production factory, often dealing with new quotes and requalification all over again.

The ideal small batch CNC service acts as a bridge. They should be able to tell you, "We made your 50 prototypes. Here's what we learned about machining this

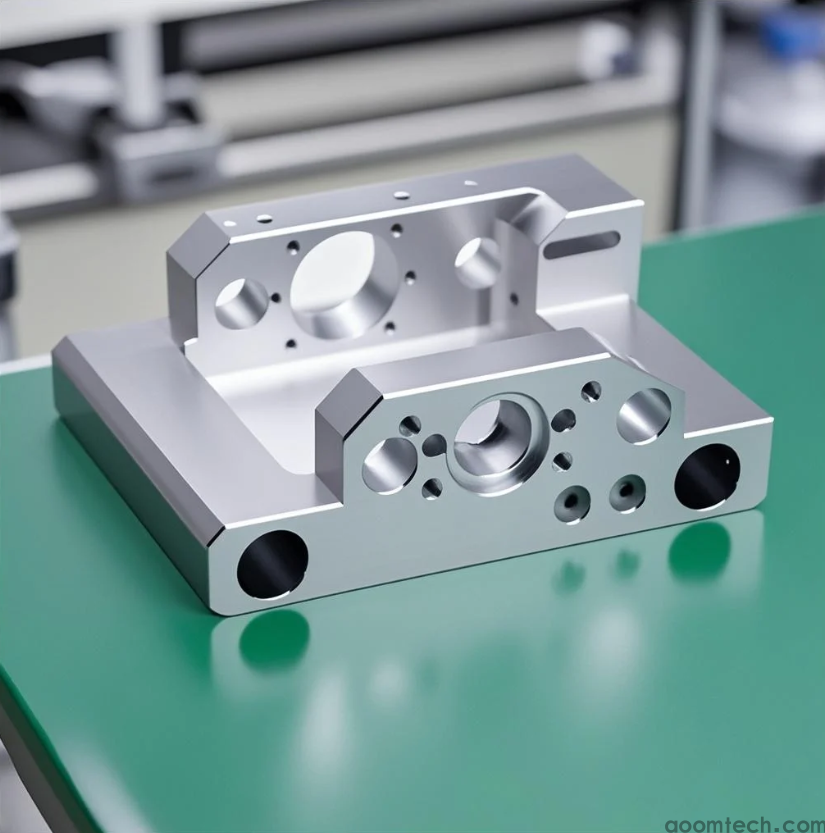

Small Batch CNC Machining Part

Small Batch CNC Machining Part

Small Batch Multi-Variety CNC

Small Batch Multi-Variety CNC

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi