How to Find Reliable CNC Machining Services for Your Project

Feeling overwhelmed by the search for a good CNC shop? You're not alone. Every day, engineers and purchasing managers face the same headache: you need high-quality parts, on time and within budget, but finding a trustworthy supplier feels like a gamble. The market is flooded with options, yet consistent quality and clear communication seem hard to come by. This guide cuts through the noise, offering a straightforward path to identify and partner with a CNC machining service that won't let you down.

What Exactly Should You Look For in a CNC Machining Partner?

This is the core question. The answer isn't just about the machines; it's about the process, people, and proof. A reliable partner operates with transparency, has a system for quality control, and treats your project as if it were their own. Think of it as hiring a team member, not just buying a service.

Key Factors Beyond the Price Tag

While cost is crucial, fixating only on the lowest quote is a classic pitfall. Here’s what matters more:

1. Communication & Technical Support: Can you easily discuss technical drawings? A good partner will ask questions and suggest optimizations for machinability and cost-saving. If they just say "yes" to everything without input, be cautious.

2. Quality Control Process: Do they have documented QC steps? First-article inspection (FAI) reports? Ask about their measurement tools and how they handle non-conforming parts. This is non-negotiable.

3. Project Management: Who is your single point of contact? A dedicated project manager can prevent delays and confusion, making the entire supply chain coordination smoother.

The Practical Steps to Vet a Supplier

Okay, so how do you check these boxes? Here's a plan you can use right now:

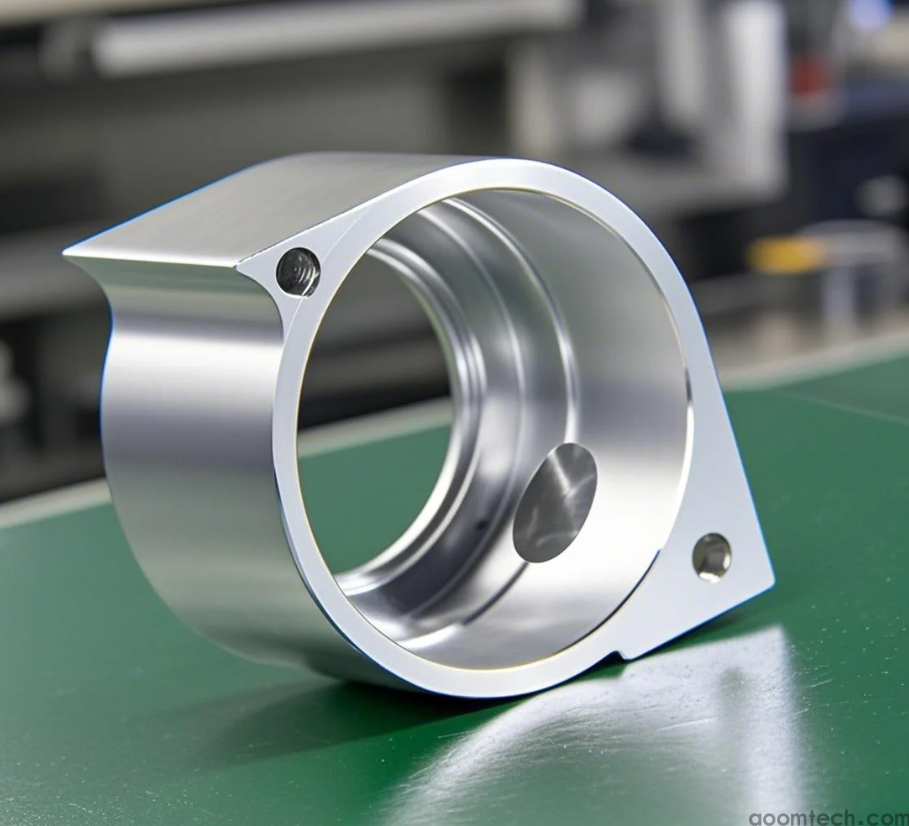

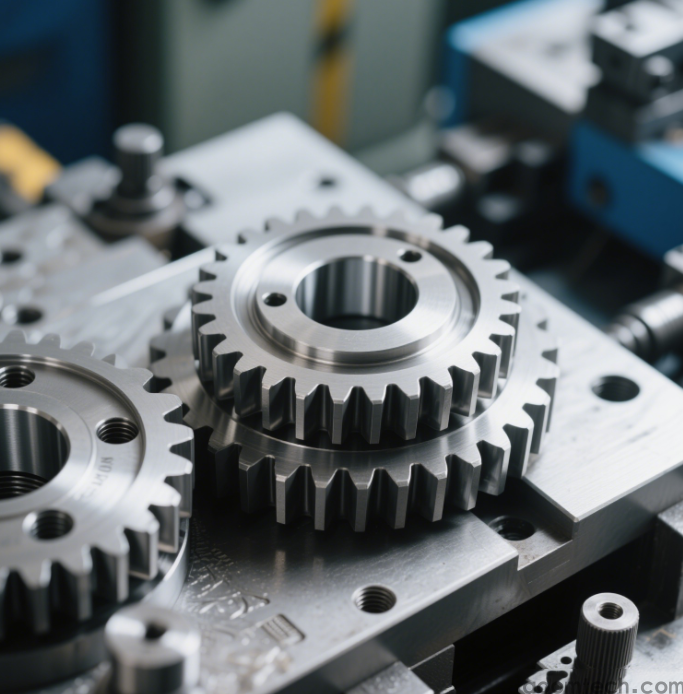

Step 1: The Initial Audit. Request a capability sheet and visit their website (or facility if possible). Look for case studies similar to your project, whether it's precision aerospace components or durable industrial machinery parts.

Step 2: The Test Question. Send a detailed RFQ with a complex drawing. Gauge their response time and the quality of their questions. Do they suggest changing a tight tolerance that's unnecessary, potentially saving you money? That's a good sign.

Step 3: The Small Order. Before committing to a large batch, place a small pilot order. This tests their on-time delivery, quality, and packaging. It's the most reliable proof.

From my experience, this last step separates the best from the rest. I've seen shops deliver flawless samples but struggle with production consistency. A pilot run reveals their true colors.

Common Red Flags You Shouldn't Ignore

Being aware of warning signs can save you months of trouble. Watch out for:

- Vague or evasive answers to technical questions.

- No request for a formal drawing or 3D model.

- Unwillingness to provide references or samples of past work.

- Extremely low prices that seem too good to be true (they usually are).

- Lack of a clear contract or terms covering confidentiality, quality standards, and liability.

However, it's worth mentioning that a newer shop might not have a vast portfolio but could offer great service and value. The key is their willingness to prove themselves through action, not just talk.

Making the Final Decision and Building the Relationship

You've gathered quotes, reviewed capabilities, and maybe even tested with a small order. Now what? Don't just pick the cheapest. Weigh the overall value: reliability, communication ease, and technical expertise. A slightly higher price for peace of mind is often the smarter business decision.

A true partnership means they become an extension of your team. Share your long-term plans; a good supplier will help you plan for material procurement and scale production. This collaborative approach is, in my view, the ultimate goal. It transforms a simple vendor transaction into a strategic advantage.

Ready to move forward with a partner who prioritizes your project's success? The next step is to have a detailed conversation. Our team specializes in turning complex designs into precision-made parts, with a focus on transparent communication and rigorous quality checks. Let's discuss your specific requirements and how we can deliver value beyond the quote.

A final thought: In this industry, the smoothest projects often have the most conversations behind them. Never underestimate the value of a supplier who listens as much as they machine. 🛠️

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How Much Does Small Batch CNC

How Much Does Small Batch CNC

How to Prevent Deformation in

How to Prevent Deformation in