How to Find Reliable CNC Machining Services for Aluminum Parts?

Feeling overwhelmed by countless CNC machining quotes for your aluminum project? You're not alone. Many engineers and purchasing managers struggle to find a shop that balances quality, cost, and reliability. The search often leads to generic results or suppliers who overpromise. So, how do you cut through the noise and find a partner that truly understands precision aluminum machining? Let's dive in.

What Makes a "Reliable" CNC Service for Aluminum?

This is the core question. A reliable service isn't just about having fancy machines. It's about consistent precision, clear communication, and delivering on promises. For aluminum parts, reliability means understanding the material's quirks—like its tendency to gum up tools or its need for specific coolants. A good shop will proactively discuss these details with you, rather than just sending a price.

Key Factors to Vet Your Potential Supplier

Don't just look at the price. Here’s what matters more:

- Material Expertise: Do they have experience with various aluminum grades (like 6061, 7075)? Can they advise on the best one for your application?

- Quality Control Process: Ask about their inspection equipment (e.g., CMMs, calipers) and quality certifications. Do they provide inspection reports?

- Communication & Project Management: Is there a dedicated point of contact? How do they handle design feedback or schedule updates? Smooth communication prevents costly errors.

I've found that shops willing to explain their process in simple terms are often more trustworthy. It shows they're confident and client-focused.

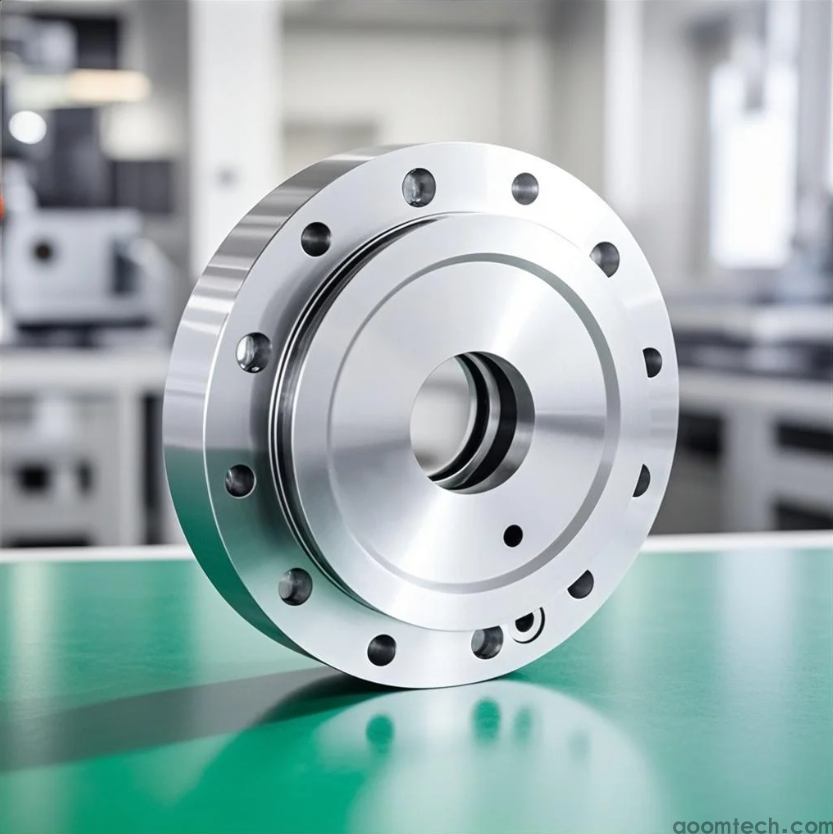

The Hidden Challenge: Surface Finish and Tolerance

Anyone can cut aluminum. But achieving a perfect anodized finish or holding a tight tolerance like ±.01mm is where skill shines. A common pitfall is not specifying finish requirements early, leading to extra cost and delay.

My advice? Always provide a detailed technical drawing. If you're unsure about tolerances for non-critical features, a reliable engineer from the shop should guide you toward a cost-effective standard. This collaboration is key.

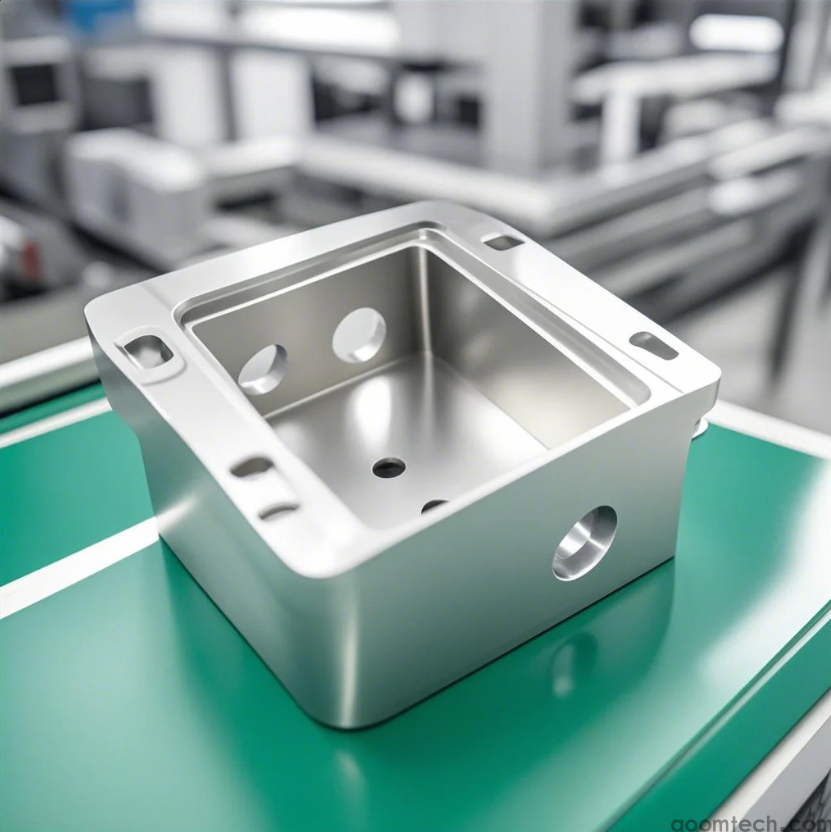

Why Small Batches Can Be Trickier Than Mass Production

It might seem counterintuitive, but getting high-quality, small-batch prototypes or initial production runs can be harder. Large factories often prefer big orders. The best partners for this are agile shops with quick setup processes. They value building long-term relationships, even starting with small orders.

However, keep in mind that unit cost will be higher for small batches—this is normal due to setup time. A transparent supplier will explain this breakdown, not hide it.

Your Action Plan: Questions to Ask Before Ordering

Ready to engage? Arm yourself with these questions:

- "Can you walk me through your workflow for a part like this?"

- "What is your lead time for a 5-piece batch, and what could cause delays?"

- "Can you share a case study or sample of a similar aluminum part you've machined?"

Asking these separates the order-takers from the true partners. A partner's answers will be specific and reassuring.

Finding the right CNC machining service is a mix of clear specs and finding a shop that listens. The goal is a partnership where quality is assumed, not just promised. It might take a few more emails, but the saved time, cost, and headache down the line are worth it.

Need a second opinion on your aluminum part design or a current quote? Sometimes, a fresh, expert look can identify potential issues or cost savings. Getting that insight early makes all the difference. 👉 [Reach out to our technical team for a confidential review].

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How Much Does Small Batch CNC

How Much Does Small Batch CNC

How to Prevent Deformation in

How to Prevent Deformation in