CNC Machining Brass Process

Understanding the Basics of CNC Machining Brass

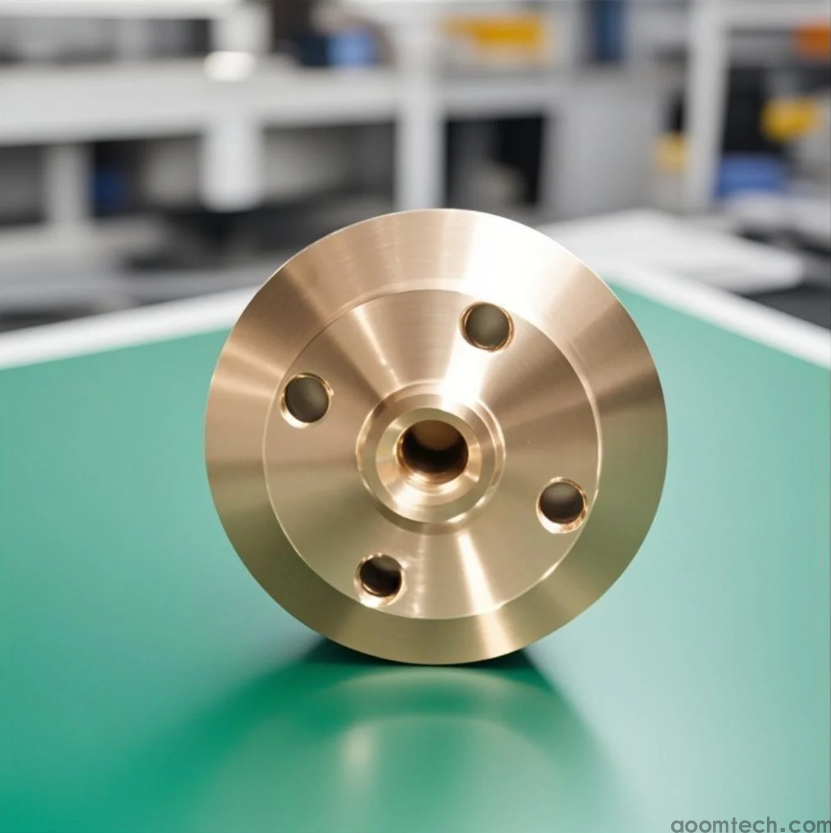

Brass is one of the most popular materials for CNC machining due to its excellent machinability, corrosion resistance, and aesthetic appeal. At AOOM, we specialize in precision CNC machining brass components for various industries including automotive, electronics, and plumbing.

Key Advantages of Brass in CNC Machining

Brass offers several benefits that make it ideal for CNC machining processes:

Superior machinability with minimal tool wear

Excellent thermal and electrical conductivity

Natural corrosion resistance

Attractive gold-like appearance

Good strength-to-weight ratio

Our CNC Machining Brass Capabilities

AOOM's advanced CNC machining center handles brass components with precision and efficiency. Our capabilities include:

3-axis, 4-axis, and 5-axis CNC milling

CNC turning for cylindrical brass parts

High-speed machining for complex geometries

Tight tolerance machining (±.005mm)

Surface finishing options (polishing, plating, anodizing)

Quality Assurance in Brass CNC Machining

We implement strict quality control measures throughout our CNC machining brass process:

Material certification verification

In-process dimensional inspections

Surface finish evaluation

Final comprehensive quality check

Traceability documentation

Applications of CNC Machined Brass Parts

Our CNC machined brass components serve various industries:

Precision valves and fittings for plumbing systems

Electrical connectors and terminals

Decorative hardware and architectural elements

Marine components requiring corrosion resistance

Musical instrument parts

Why Choose AOOM for Your Brass CNC Machining Needs

As a professional CNC machining service provider, AOOM offers:

Extensive experience with brass materials

State-of-the-art CNC equipment

Skilled machinists and engineers

Competitive pricing and fast turnaround

Custom solutions for unique requirements

Visit our website at www.aoomtech.com to learn more about our CNC machining brass capabilities and request a quote for your project.

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How Much Does Small Batch CNC

How Much Does Small Batch CNC

How to Prevent Deformation in

How to Prevent Deformation in