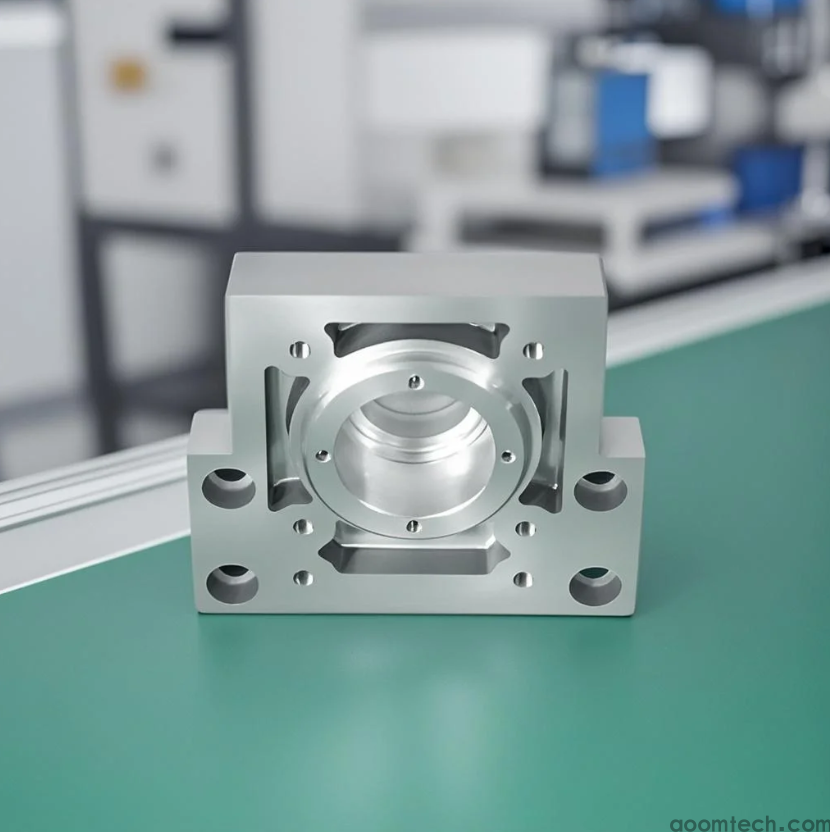

Aircraft Parts CNC Machining Process

As a professional CNC machining service provider, AOOM Technology specializes in manufacturing high-precision aircraft parts with strict adherence to aerospace industry standards. This article will explore the critical aspects of CNC machining processes for aviation components.

1. Material Selection for Aircraft Components

The machining process begins with selecting aerospace-grade materials like titanium alloys, aluminum 7075, or Inconel. These materials offer exceptional strength-to-weight ratios and corrosion resistance required for flight applications.

2. Precision Machining Techniques

Our 5-axis CNC machines achieve tolerances within ±.001 inches, ensuring perfect fit and function for critical flight components. Advanced toolpath programming optimizes material removal while maintaining structural integrity.

3. Quality Control Measures

Every aircraft part undergoes rigorous inspection using CMM (Coordinate Measuring Machines) and laser scanning to verify dimensional accuracy. We maintain complete traceability from raw material to finished product.

4. Surface Treatment Options

Depending on application requirements, we offer various surface treatments including anodizing, passivation, and specialized coatings to enhance durability and performance.

Why Choose AOOM for Aircraft CNC Machining?

With AS910D certification and decades of aerospace machining experience, AOOM Technology delivers:

Strict compliance with aviation safety standards

Advanced CNC equipment specifically calibrated for aerospace materials

Comprehensive quality management system

Competitive lead times without compromising precision

For more information about our aircraft parts manufacturing capabilities, visit our website at www.aoomtech.com or contact our engineering team for project consultation.

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How Much Does Small Batch CNC

How Much Does Small Batch CNC

How to Prevent Deformation in

How to Prevent Deformation in