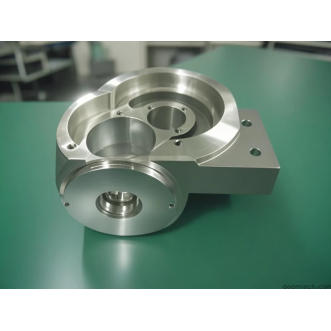

CNC Worm Gear Machining: Presisjonsløsninger for dine mekaniske behov

Innen mekanisk kraftoverføring, CNC worm gear machining stands as a critical process for creating high-efficiency, low-noise components. At AOOM, we specialize in delivering precision-engineered worm gears that meet the most demanding industry standards.

Hva er CNC Worm Gear Machining?

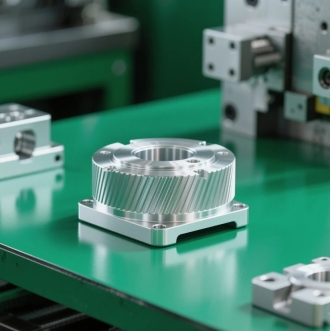

CNC ormutstyrsbearbeiding innebærer datastyrt produksjon av ormutstyr og ormer - viktige komponenter i rettvinkelgirstasjoner. Våre avanserte CNC machining capabilities allow us to produce these complex geometries with micron-level accuracy, ensuring perfect meshing and optimal torque transmission.

Viktige fordeler med vår CNC Worm Gear Machining

1. Precision Engineering: Our 5-axis CNC machines achieve tight tolerances (±.005mm) for smooth operation

2. Material Versatility: We machine worm gears from steel, bronze, aluminum, and engineering plastics

3. Custom Solutions: Tailored designs for specific speed ratios, load capacities, and space constraints

4. Surface Finishing: Optional grinding, polishing, and heat treatment for enhanced durability

Bransjer vi betjener

Våre CNC worm gear machining services support diverse applications including:

Automotive steering systems

Industrial conveyor equipment

Robotics and automation

Elevator and lifting mechanisms

Precision instrumentation

Hvorfor velge AOOM for dine Worm Gear behov?

Med ISO 9001-sertifiserte fasiliteter og team av erfarne maskinister, leverer AOOM:

Rapid prototyping with 3-5 day turnaround

Full-service from design to post-processing

Strict quality control with CMM inspection

Competitive pricing for both small and large batches

Kontakt ingeniørteamet vårt i dag for å diskutere kravene til ormutstyr og oppdag hvordan vår CNC-bearbeidingskompetanse kan optimalisere de mekaniske systemene dine.