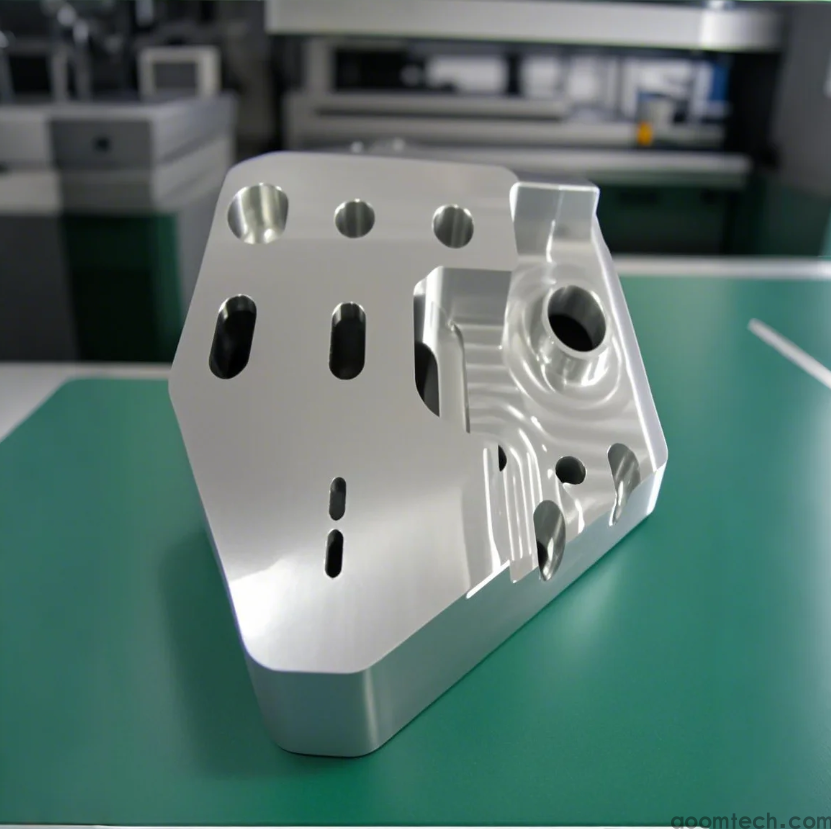

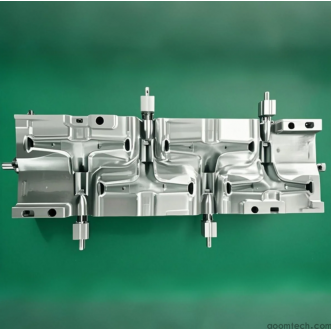

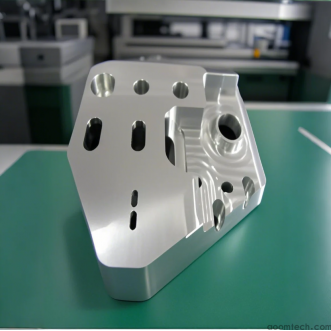

Aluminium deler CNC maskinering prosess

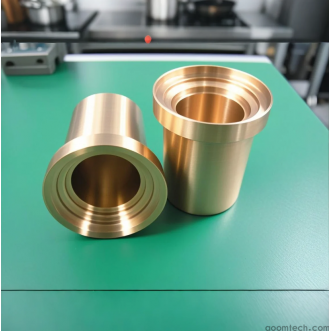

Som profesjonell CNC machining service provider, AOOM Technology specializes in precision manufacturing of aluminum components for industries ranging from aerospace to automotive. This article explores the technical nuances of aluminum parts CNC machining, addressing key concerns for procurement managers and engineers.

Hvorfor velge aluminium for CNC maskinering?

Aluminiumlegeringer (f.eks. 6061, 7075) er foretrukket for deres utmerkede styrke-til-vekt-forhold, korrosjonsmotstand og bearbeidbarhet. Vår CNC machining center utilizes advanced 5-axis machines to achieve tolerances as tight as ±.005mm, making aluminum ideal for complex prototypes and high-volume production.

Nøkkeltrinn i aluminium CNC maskinering

1. Material Selection: We help clients choose optimal alloys based on application requirements.

2. CAD/CAM Programming: Our engineers convert designs into machine-readable G-codes with collision-free toolpaths.

3. Precision Machining: High-speed spindles (up to 20,000 RPM) ensure superior surface finishes (Ra .8μm achievable).

4. Quality Control: CMM inspection and ISO 9001-certified processes guarantee dimensional accuracy.

AOOMs tekniske fordeler

• 10+ Years Expertise: 500+ successful aluminum machining projects completed

• Advanced Equipment: 20+ CNC mills with automatic tool changers

• Value-added Services: Anodizing, powder coating, and heat treatment available

Besøk aoomtech.com to request a free DFM analysis for your aluminum components. Our team delivers high-precision parts within 5-15 working days, combining German-engineered machinery with Chinese manufacturing efficiency.