Precision CNC maskinering tilpasning

I moderne produksjon, precision CNC machining customization is a critical solution for industries requiring high-accuracy, complex components. Whether for aerospace, medical devices, or automotive applications, customized CNC machining ensures parts meet exact specifications with exceptional repeatability. At AOOM, we specialize in delivering tailored CNC solutions that combine advanced technology with rigorous quality control.

Hvorfor velge tilpasset CNC Machining?

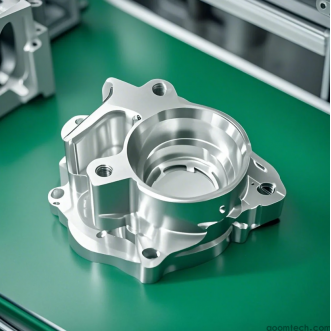

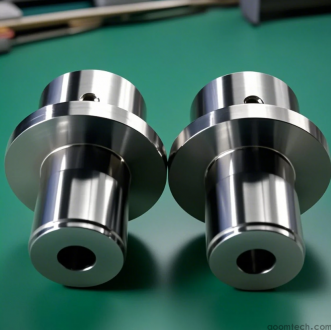

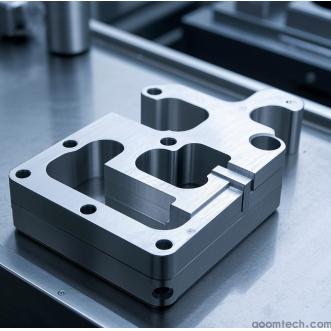

Egendefinert CNC-bearbeiding gir enestående fleksibilitet for å produsere deler med stramme toleranser og intrikate geometrier. I motsetning til standard maskinering, precision CNC customization adapts to unique design requirements, material preferences, and functional demands. Our capabilities include multi-axis milling, turning, and Swiss machining, enabling us to handle prototypes to high-volume production runs.

Viktige fordeler med AOOMs CNC-tilpasning

1. Advanced Equipment: Our facility houses state-of-the-art CNC machines (e.g., 5-axis mills, lathes) to ensure micron-level accuracy.

2. Material Expertise: We work with metals (aluminum, titanium), plastics, and exotic alloys, optimizing machining parameters for each.

3. Quality Assurance: Every custom part undergoes rigorous inspection via CMMs and surface analyzers to guarantee compliance.

4. Fast Turnaround: Streamlined workflows and in-house tooling reduce lead times without compromising precision.

Anvendelser av tilpassede CNC-bearbeidede deler

Fra luftfartsbraketter til medisinske implantater, CNC-machined custom components are vital across industries. AOOM’s projects include:

- High-strength automotive prototypes

- Corrosion-resistant marine fittings

- Biocompatible surgical instruments

Partner med AOOM for presisjons CNC-bearbeiding skreddersydd til dine eksakte behov. Besøk aoomtech.com to request a quote or discuss your project with our engineers today.