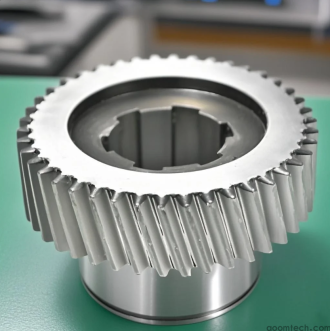

CNC Machining Metal Gear

Hvorfor velge CNC Machining for Metal Gears?

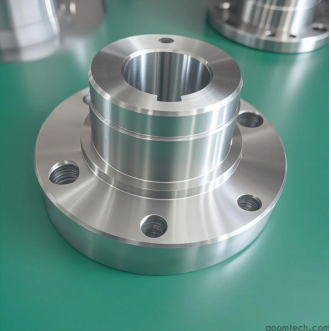

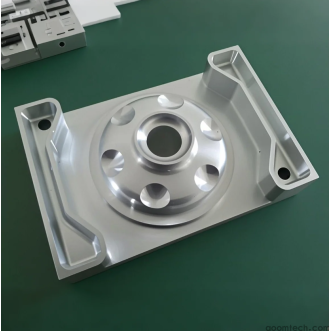

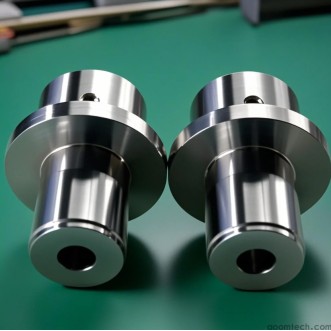

Metallgir er kritiske komponenter i bransjer som bilindustri, luftfart og industrielle maskiner. CNC machining offers unparalleled precision, durability, and customization for gear manufacturing. At AOOM, we specialize in producing high-quality metal gears with tight tolerances and superior surface finishes.

Fordeler med CNC Machined Metal Gears

1. High Precision: CNC machines ensure micron-level accuracy, essential for smooth gear operation. 2. Material Versatility: We work with stainless steel, aluminum, brass, and titanium. 3. Complex Geometries: CNC technology allows for intricate tooth profiles and custom designs. 4. Consistency: Perfect for high-volume production with identical specifications.

Vår CNC Gear produksjonsprosess

1. Design Analysis: Our engineers review your gear specifications and optimize the design for manufacturability. 2. Material Selection: We help choose the ideal metal alloy for your application. 3. Precision Machining: Using advanced 5-axis CNC machines for complex gear teeth cutting. 4. Quality Control: Every gear undergoes rigorous inspection for dimensional accuracy and performance.

Applikasjoner av CNC-bearbeidede metallgir

Våre CNC machined gears are used in: • Automotive transmissions • Robotics and automation systems • Industrial gearboxes • Aerospace mechanisms • Medical equipment

Hvorfor samarbeide med AOOM for dine utstyrsbehov?

Som en ledende leverandør av CNC-maskinering tilbyr AOOM: • Toppmoderne CNC utstyr • Erfarne maskiningeniører • Konkurransedyktige priser for både prototyper og masseproduksjon • Strengt kvalitetsstyringssystem (ISO 9001-sertifisert) • Raske turnaround-tider uten å kompromittere kvaliteten

Kontakt AOOM i dag for dine tilpassede metallutstyrskrav. Besøk nettstedet vårt på www.aoomtech.com to learn more about our CNC machining capabilities.