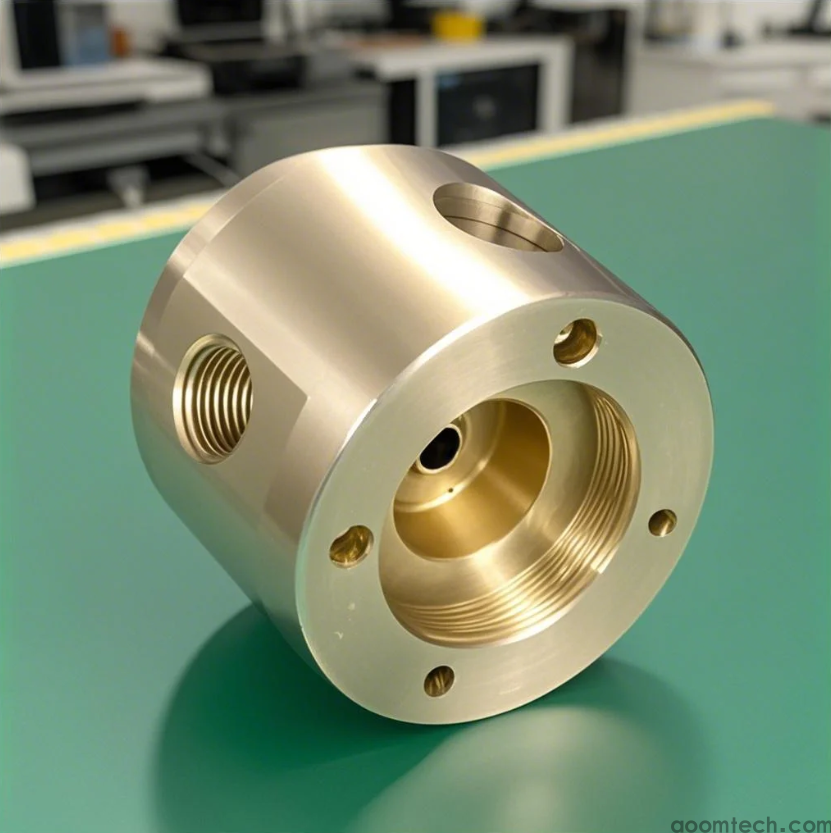

CNC Machining Precision Copper Materials

In modern manufacturing, CNC machining precision copper materials has become a critical process for industries requiring excellent electrical conductivity, thermal performance, and corrosion resistance. As a leading CNC machining service provider, AOOM Technology delivers exceptional copper component manufacturing solutions for electronics, automotive, and aerospace applications.

Why Choose CNC Machining for Copper Materials?

Copper's unique properties demand specialized machining approaches. Our CNC precision machining capabilities ensure:

- ±.005mm dimensional accuracy for tight-tolerance copper parts

- Optimized tool paths to prevent material deformation

- Superior surface finishes (up to Ra .8μm)

- Efficient chip removal and heat management

AOOM's Advanced Copper Machining Capabilities

Our 5-axis CNC centers equipped with high-speed spindles (up to 30,000 RPM) handle complex copper geometries including:

- Electrical connectors and busbars

- Heat sinks and thermal management components

- Waveguide components for RF applications

- Precision bearings and bushings

Quality Assurance Process

Every copper component undergoes rigorous inspection:

- CMM measurement for dimensional verification

- Conductivity testing (to ASTM B193 standards)

- Surface roughness analysis

- Visual inspection under 10x magnification

At AOOM Technology, we combine advanced CNC equipment with metallurgical expertise to deliver precision copper parts that meet your most demanding specifications. Contact our engineering team to discuss your copper machining requirements.