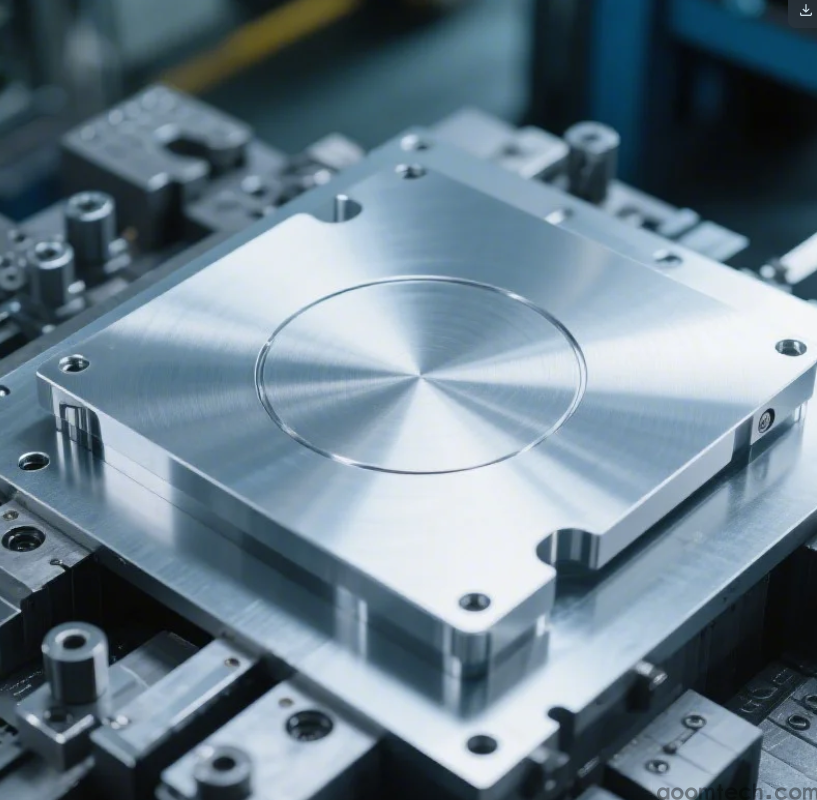

CNC Large Part Machining: Precision Solutions for Industrial Applications

In modern manufacturing, CNC large part machining plays a pivotal role in producing high-precision components for aerospace, automotive, and heavy machinery industries. As a leading CNC machining service provider, AOOM Technology specializes in handling oversized workpieces with micron-level accuracy through advanced 5-axis milling and turning capabilities.

Why Choose CNC Machining for Large Components?

Large-scale CNC machining offers distinct advantages over traditional methods. Our 8-meter bed CNC lathes and 5-meter travel machining centers maintain ±.02mm tolerance even when processing massive parts. This eliminates assembly errors from multi-part fabrication while ensuring structural integrity for critical applications like wind turbine gearboxes or marine propulsion systems.

Material Capabilities for Oversized Parts

We machine diverse materials including aluminum alloys (6061, 7075), stainless steels (304, 316), titanium (Grade 5), and engineering plastics. Our temperature-controlled workshop prevents thermal deformation during large part machining, with in-process measurement systems verifying dimensional stability.

AOOM's Technical Advantages in Large Part Manufacturing

1. Custom Fixturing Solutions: Modular workholding systems accommodate parts up to 15-ton capacity

2. High-Speed Machining: 20,000 RPM spindles with through-tool coolant optimize cycle times

3. Surface Finish Control: Ra .4μm achievable via integrated grinding/polishing stations

Quality Assurance Process

Every large component undergoes rigorous inspection using laser trackers (accuracy: .01mm/m) and portable CMMs. Our ISO 9001-certified system includes material traceability and full documentation packages with 3D scan reports.

For project-specific CNC large part machining requirements, contact AOOM Technology at www.aoomtech.com for a free DFM analysis and quotation within 24 hours.