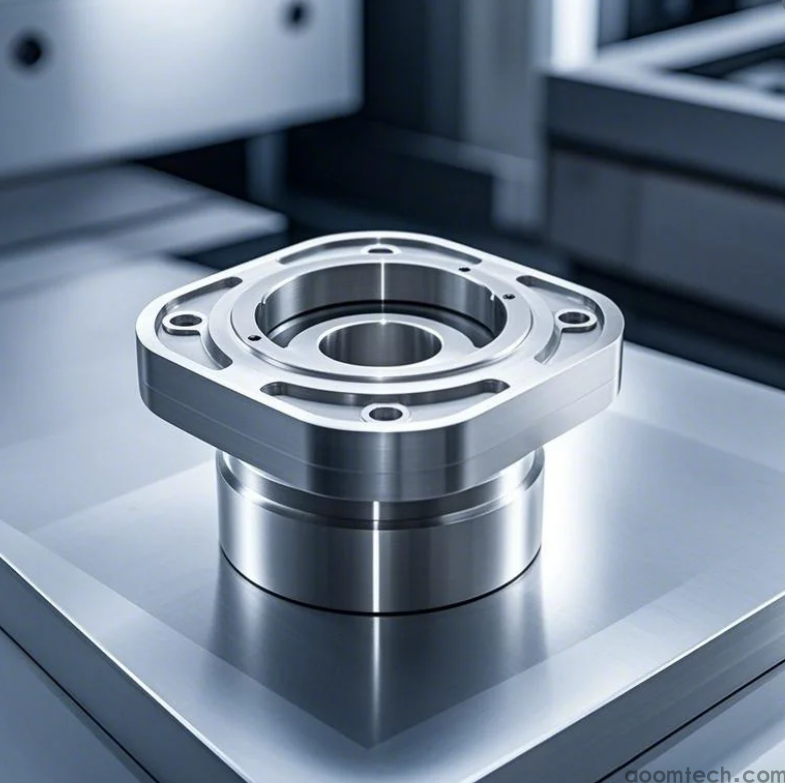

Non-Standard Custom CNC Machining

In modern manufacturing, non-standard custom CNC machining plays a pivotal role in meeting unique industrial requirements. As a professional CNC machining service provider, AOOM specializes in delivering high-precision, tailored solutions for complex components across industries.

What is Non-Standard Custom CNC Machining?

Non-standard custom CNC machining refers to the process of creating parts that don't conform to standard specifications or dimensions. Unlike mass-produced components, these parts require specialized programming, tooling, and machining techniques to achieve the desired geometry and functionality.

Key Advantages of Our Custom CNC Services

AOOM's non-standard CNC machining capabilities offer several distinct benefits:

- Precision engineering for complex geometries

- Flexible production for prototypes and small batches

- Material versatility including metals, plastics, and composites

- Strict quality control throughout the manufacturing process

Our Custom CNC Machining Process

The workflow for non-standard parts at AOOM follows these critical stages:

- Technical consultation and requirements analysis

- CAD/CAM programming for unique part geometries

- Selection of specialized cutting tools and fixtures

- Precision machining with multi-axis CNC equipment

- Comprehensive quality inspection

Industries We Serve

Our custom CNC solutions support diverse sectors including aerospace, medical devices, automotive, and industrial equipment manufacturing. We particularly excel in producing:

- Complex mechanical components

- Specialized tooling and fixtures

- Prototypes for R&D purposes

- Replacement parts for legacy equipment

With AOOM's expertise in non-standard custom CNC machining, clients receive precisely engineered components that meet their exact specifications, delivered with the quality and reliability expected from a leading CNC service provider.