Brass Precision CNC Machining for Mass Production

Understanding Brass Precision CNC Machining

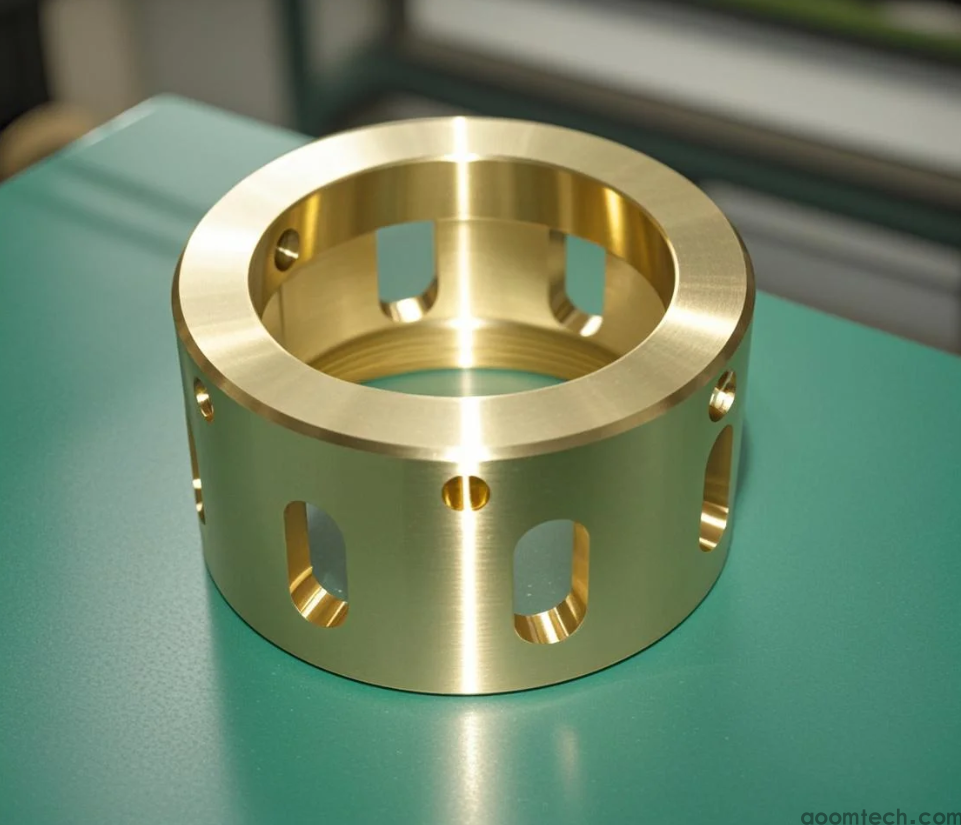

When it comes to brass precision CNC machining for mass production, manufacturers require specialized expertise to maintain tight tolerances and consistent quality across large volumes. Brass, known for its excellent machinability and corrosion resistance, is widely used in industries such as plumbing, electrical, and automotive components.

Key Advantages of CNC Machining for Brass Components

Our CNC machining processes offer several benefits for brass parts production: superior dimensional accuracy (typically within ±.005mm), excellent surface finishes (reaching Ra .8μm or better), and high repeatability across thousands of parts. The automated nature of CNC machining ensures consistent quality while keeping per-unit costs competitive for bulk orders.

Optimized Production Workflow

At AOOM, we've developed an efficient workflow for mass production of brass components: 1) Material selection (C36000 free-cutting brass preferred for most applications) 2) Precision CNC turning/milling 3) Automated deburring 4) Quality inspection (including CMM verification) 5) Protective packaging. This streamlined process minimizes lead times while maintaining the highest quality standards.

Industry-Specific Applications

Our brass CNC machining services cater to various industries: electrical connectors, precision valves, marine hardware, and decorative architectural elements. The combination of brass's natural antimicrobial properties and our precision machining capabilities makes our products ideal for medical and food processing applications where hygiene is critical.

Why Choose AOOM for Your Brass Machining Needs

With over 15 years of experience in precision CNC machining, AOOM offers: 1) Advanced 5-axis CNC machines specifically calibrated for brass 2) ISO 9001-certified quality management 3) Competitive pricing for bulk orders 4) Full DFM (Design for Manufacturing) support 5) Just-in-time delivery options. Our technical team works closely with clients to optimize designs for manufacturability and cost-efficiency.