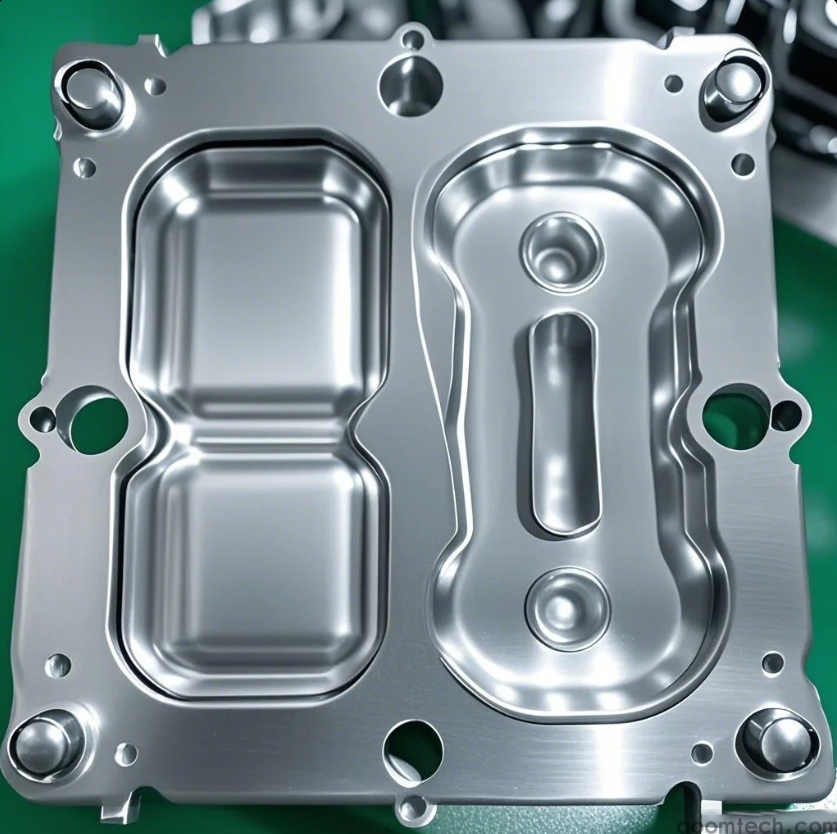

CNC Mold Processing Customization

In modern manufacturing, CNC mold processing customization plays a pivotal role in delivering high-precision components for industries ranging from automotive to consumer electronics. At AOOM, we specialize in providing tailored CNC machining solutions that meet the exacting standards of our clients.

What is CNC Mold Processing Customization?

CNC mold processing customization refers to the process of using computer numerical control (CNC) machines to create molds with specific designs and tolerances. This process is essential for producing complex parts with high accuracy and repeatability. Our advanced CNC technology ensures that each custom mold meets the unique requirements of your project.

Key Advantages of Choosing AOOM for CNC Mold Processing

1. Precision Engineering: Our state-of-the-art CNC machines guarantee tolerances as tight as ±.01mm, ensuring flawless mold production.

2. Material Versatility: We work with a wide range of materials, including aluminum, steel, and engineering plastics, to suit diverse applications.

3. Fast Turnaround: With streamlined processes and experienced technicians, we deliver custom molds without compromising on speed or quality.

The CNC Mold Customization Process at AOOM

Our CNC mold processing customization follows a rigorous workflow:

- Design Analysis: Our engineers review your CAD files to optimize manufacturability.

- Machining: High-speed CNC milling/turning transforms raw materials into precision molds.

- Quality Control: Each mold undergoes dimensional verification and surface finish inspection.

By choosing AOOM for your CNC mold needs, you gain a partner committed to excellence. Visit aoomtech.com to explore how our custom CNC solutions can elevate your production capabilities.