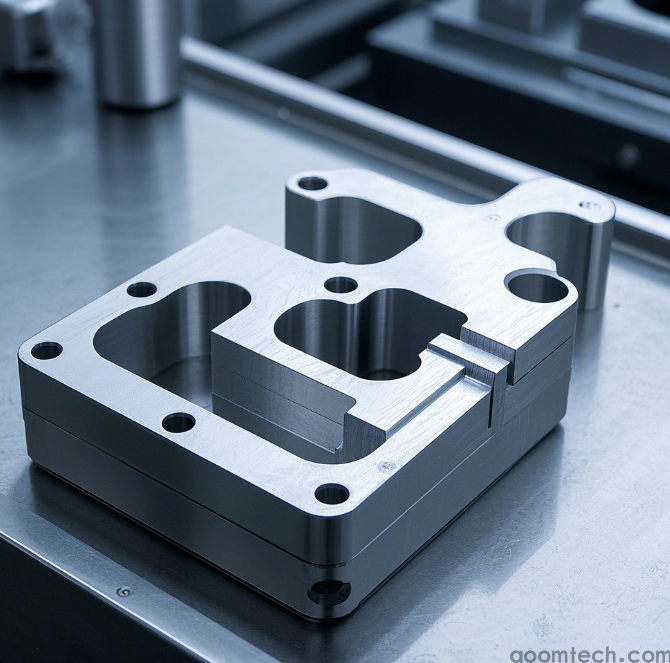

CNC Large Steel Parts Machining

In industrial manufacturing, CNC large steel parts machining represents a critical capability that demands precision, power, and technical expertise. At AOOM, we specialize in delivering high-tolerance steel components for heavy machinery, energy equipment, and aerospace applications through advanced 5-axis CNC systems.

Why Choose CNC for Large Steel Components?

Traditional machining methods struggle with the rigidity and thermal challenges of steel workpieces exceeding 1-ton weight. Our CNC machining solutions overcome these limitations through:

- High-torque spindle motors (up to 50HP) for consistent cutting performance

- Thermal compensation systems maintaining ±.02mm accuracy

- Custom fixture designs preventing workpiece deformation

Key Processes in Steel Parts Machining

Our production flow for large steel parts includes:

- Material Certification: Verification of steel grade (1045, 414, etc.) and mechanical properties

- Rough Machining: Removing 70-80% material with inserted carbide cutters

- Stress Relieving: Intermediate heat treatment to prevent warping

- Finish Machining: Achieving Ra 1.6μm or better surface finish

AOOM's Technical Advantages

With 12 years of experience in heavy-duty machining, we offer:

- Maximum workpiece capacity: 5m(L) × 2.5m(W) × 1.8m(H)

- In-house CMM inspection (Zeiss CONTURA G2)

- Mazak MEGA-TURN 160V for complex geometries

- ISO 9001-certified quality management

For your next large-scale steel component project, request a machining evaluation at www.aoomtech.com. Our engineering team provides DFM analysis within 24 hours.