CNC Aluminum Processing: A Comprehensive Guide

As a leading CNC machining service provider, AOOM Technologies specializes in precision aluminum parts manufacturing for various industries. This guide will explain the complete process of CNC aluminum machining, helping procurement managers, engineers, and business owners understand how to achieve optimal results for their projects.

Understanding CNC Aluminum Machining

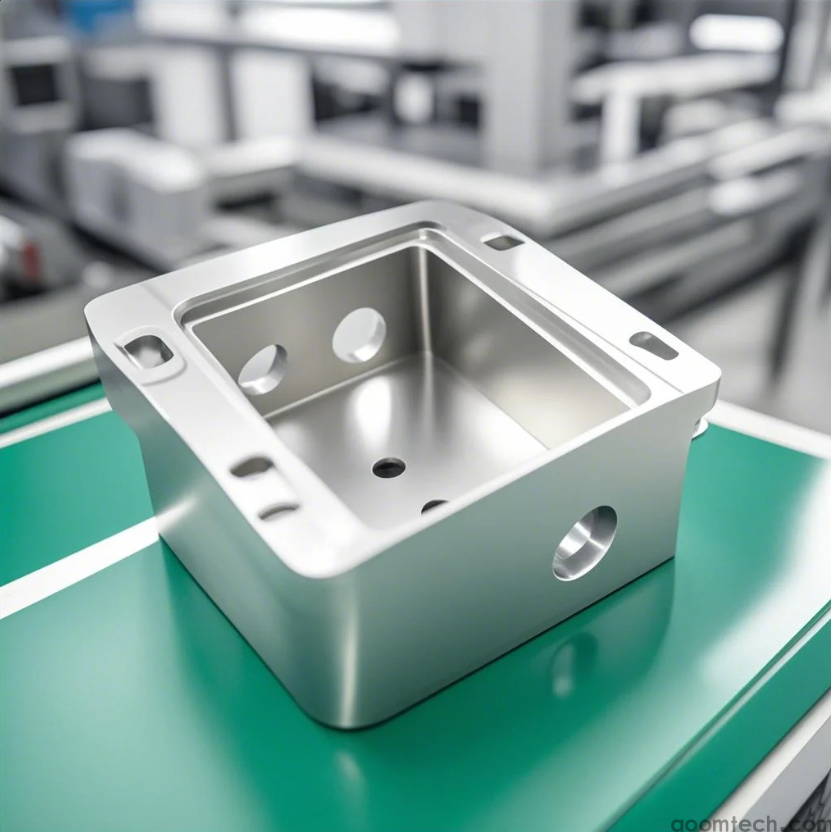

CNC (Computer Numerical Control) aluminum machining refers to the process of using computer-controlled machines to precisely cut, shape, and finish aluminum materials. Aluminum is one of the most commonly machined metals due to its excellent machinability, strength-to-weight ratio, and corrosion resistance.

The CNC Aluminum Machining Process

1. Material selection: Choosing the right aluminum alloy (6061, 7075, 5052, etc.) based on application requirements

2. CAD design: Creating or converting 3D models into machine-readable formats

3. CAM programming: Generating toolpaths and machining instructions

4. Machine setup: Installing proper cutting tools and fixtures

5. Machining operations: Milling, turning, drilling, or other processes

6. Quality inspection: Verifying dimensional accuracy and surface finish

7. Post-processing: Applying treatments like anodizing or powder coating

Advantages of CNC Aluminum Machining

• High precision and repeatability (±.005" or better)

• Excellent surface finishes (up to Ra .8μm)

• Complex geometries achievable in single setup

• Faster production compared to manual machining

• Cost-effective for both prototypes and mass production

Why Choose AOOM for Your Aluminum CNC Needs?

At AOOM Technologies, we combine advanced CNC machining centers with decades of aluminum machining expertise to deliver:

- Strict quality control with ISO 9001 certification

- Quick turnaround times (as fast as 24 hours for prototypes)

- Competitive pricing with no hidden costs

- Comprehensive post-processing options

- Dedicated engineering support throughout your project

Applications of CNC Machined Aluminum Parts

Our precision aluminum components serve industries including:

• Aerospace (structural components, brackets)

• Automotive (engine parts, housings)

• Electronics (heat sinks, enclosures)

• Medical (surgical instruments, device components)

• Robotics (arms, joints, mounting plates)

For your next aluminum machining project, trust AOOM Technologies to deliver precision, quality, and reliability. Contact us today for a free quote and design consultation.