Copper Block CNC Machining: Precision Manufacturing for Industrial Applications

When it comes to copper block CNC machining, manufacturers demand exceptional thermal conductivity, corrosion resistance, and dimensional accuracy. As a leading CNC machining service provider, AOOM Technologies specializes in transforming raw copper blocks into high-performance components for electronics, aerospace, and automotive industries.

Why Choose CNC Machining for Copper Blocks?

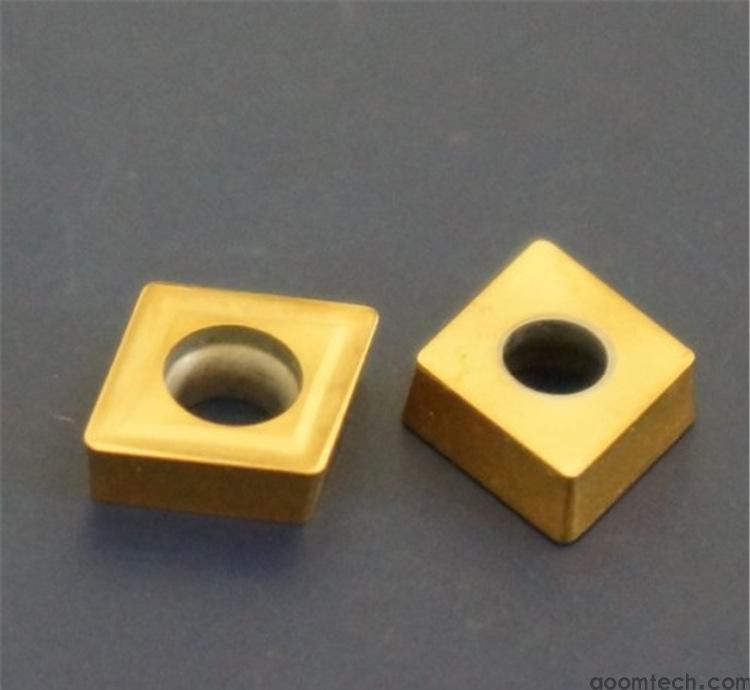

Copper's soft yet thermally efficient properties require specialized machining approaches. Our 5-axis CNC centers equipped with carbide tools ensure burr-free edges and tolerances within ±.005mm. The process involves:

- Material certification verification

- Custom fixture design to prevent deformation

- Optimized cutting parameters (speed/feed/coolant)

- Post-machining deburring & surface treatment

AOOM's Technical Advantages in Copper Machining

Our copper block CNC machining capabilities stand out through:

- 15+ years of non-ferrous metal machining experience

- In-house metallurgical lab for material analysis

- ISO 9001-certified quality control processes

- Prototype-to-mass production scalability

Critical Applications of Machined Copper Components

Precision-machined copper blocks serve as heat sinks, busbars, and waveguide components in:

- EV battery thermal management systems

- High-frequency RF equipment

- Semiconductor manufacturing tools

With copper block CNC machining projects, AOOM delivers not just parts but comprehensive manufacturing solutions - from DFM feedback to final inspection reports. Contact our engineering team at www.aoomtech.com for customized copper machining proposals.