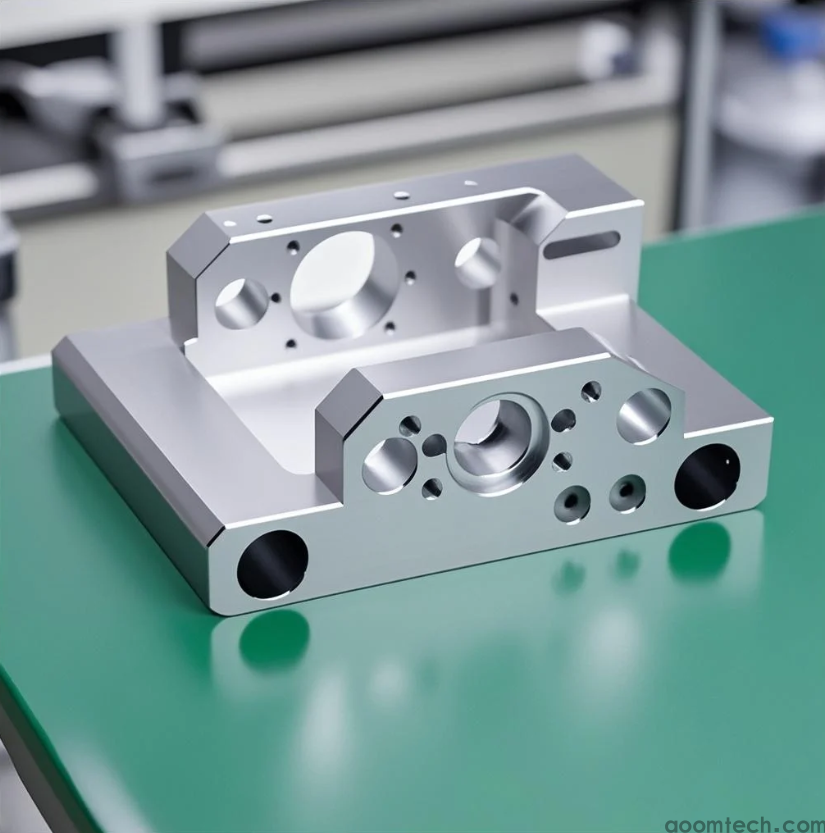

CNC Batch Processing of Aluminum Alloys

As a leading CNC machining service provider, AOOM specializes in high-precision batch processing of aluminum alloys for industries ranging from aerospace to automotive. This article explores the technical advantages, process flow, and why AOOM stands out in delivering mass-production solutions.

Why Choose CNC for Aluminum Alloy Batch Production?

Aluminum alloys (e.g., 6061, 7075) are favored for their lightweight and machinability. CNC batch processing ensures consistent quality across large volumes with tolerances up to ±.01mm. Our 5-axis machines and automated tool changers enable complex geometries (e.g., heat sinks, enclosures) with 24/7 efficiency.

AOOM's 6-Step Batch Machining Workflow

1. Material Certification: Verify alloy grade and properties.

2. Fixture Optimization: Custom jigs for multi-part clamping.

3. Toolpath Programming: CAM software minimizes tool wear.

4. In-Process Inspection: Probing checks critical dimensions.

5. Deburring & Surface Treatment: Anodizing/sandblasting options.

6. Final QC: CMM verification before shipment.

Cost-Saving Strategies for Bulk Orders

We reduce per-unit costs through:

- Nesting multiple parts on single billets

- Predictive maintenance to avoid downtime

- Recyclable chip management systems

Visit AOOM's official website to request a DFM analysis for your next aluminum project.