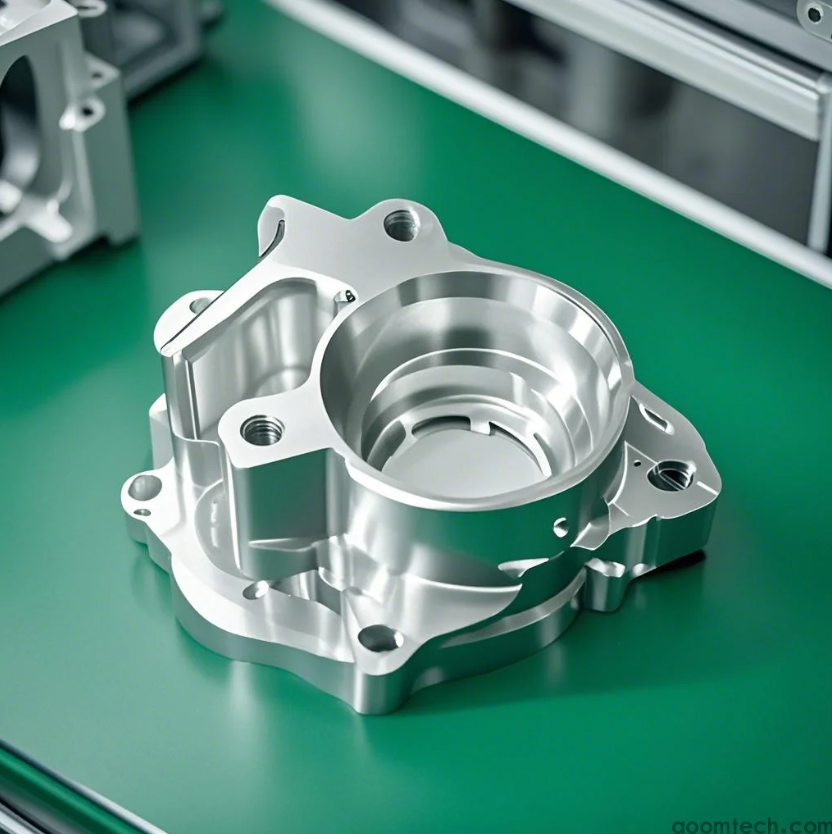

CNC Automotive Parts Precision Machining

In modern automotive manufacturing, CNC automotive parts precision machining has become the gold standard for producing high-performance components with micron-level accuracy. As a leading CNC machining service provider, AOOM Technology delivers cutting-edge solutions for automotive OEMs and aftermarket suppliers worldwide.

Why CNC Machining is Critical for Automotive Components

The automotive industry demands extreme precision, durability, and consistency - all hallmarks of CNC precision machining. Our 5-axis CNC centers produce complex geometries for engine blocks, transmission housings, suspension components, and braking systems with tolerances as tight as ±.005mm.

AOOM's Advanced Capabilities

Our 15,000㎡ facility houses:

32 high-speed CNC machining centers (Mazak, DMG Mori)

In-house CMM inspection equipment

Automated finishing/polishing stations

Material testing laboratory

Materials Expertise

We machine all automotive-grade materials including aluminum alloys (6061, 7075), stainless steels (303, 304), titanium, and engineering plastics like PEEK and Delrin.

Quality Assurance Process

Every part undergoes:

First-article inspection

In-process dimensional checks

Surface roughness verification

Final CMM validation

Industry Applications

Our automotive clients utilize our CNC parts for:

Electric vehicle battery enclosures

Fuel injection systems

Steering components

Performance drivetrain parts

With ISO 9001:2015 certification and IATF 16949 compliance, AOOM Technology guarantees automotive-grade precision for your most demanding applications. Contact our engineering team today at www.aoomtech.com for a free DFM analysis.