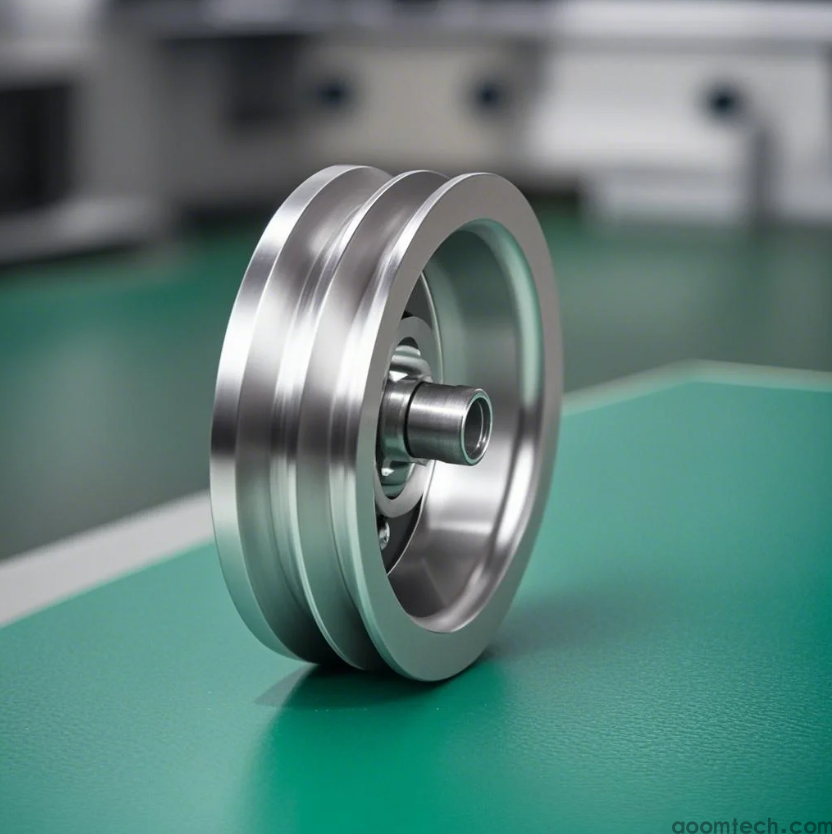

CNC Machining Pulleys: Precision Engineering for Optimal Performance

When it comes to CNC machining pulleys, precision and durability are non-negotiable. At AOOM, we specialize in manufacturing high-performance pulleys using advanced CNC technology, ensuring unmatched accuracy and reliability for industrial applications.

Why Choose CNC Machined Pulleys?

Traditional pulley manufacturing methods often compromise on dimensional accuracy and material integrity. Our CNC machining process eliminates these issues by:

Delivering tolerances within ±.01mm for perfect belt alignment

Enabling complex groove profiles for specialized transmission systems

Maintaining material strength through controlled machining temperatures

Materials We Work With

We CNC machine pulleys from various materials to meet different operational demands:

Aluminum alloys: Lightweight yet durable (6061-T6, 7075)

Stainless steel: For corrosive environments (304, 316 grades)

Engineering plastics: When noise reduction is critical (POM, Nylon)

Our CNC Machining Capabilities

AOOM's 5-axis CNC centers produce pulleys with:

Precision-balanced designs reducing vibration by up to 70%

Custom tooth profiles for specific belt types (HTD, GT, MXL)

Surface finishes from Ra .8μm to 3.2μm as required

Quality Assurance Process

Every pulley undergoes rigorous inspection including:

CMM measurements verifying all critical dimensions

Dynamic balancing tests at operational RPMs

Material certification and traceability documentation

Whether you need standard timing pulleys or custom-designed solutions, our CNC machining expertise ensures optimal power transmission performance. Contact AOOM today to discuss your pulley requirements with our engineering team.