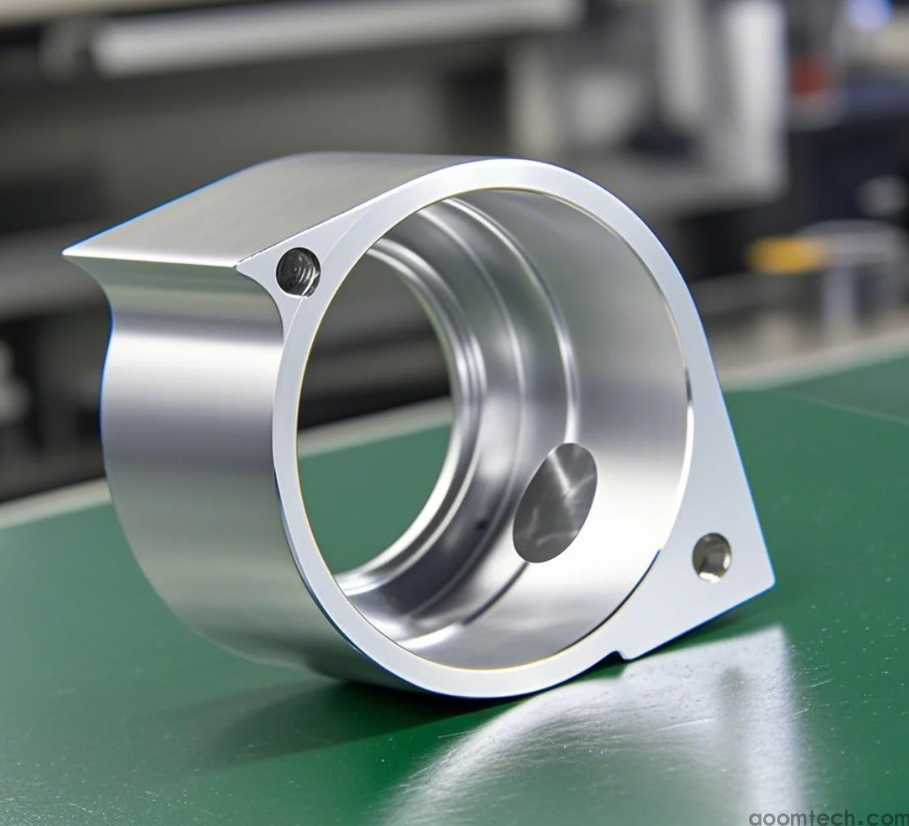

CNC Machining Precision Aluminum Parts

As a leading CNC machining service provider, AOOM Technology specializes in manufacturing high-precision aluminum components for industries ranging from aerospace to automotive. This article explores the technical process, quality control measures, and why precision matters in aluminum part fabrication.

Why Choose CNC for Precision Aluminum Parts?

Computer Numerical Control (CNC) machining offers micron-level accuracy when producing precision aluminum parts. The non-ferrous properties of aluminum alloys (6061, 7075, etc.) make them ideal for CNC processes, combining lightweight characteristics with excellent machinability. Our 5-axis CNC centers achieve tolerances as tight as ±.005mm for critical dimensions.

Key Processes in Aluminum CNC Machining

1. Material Selection: We use aerospace-grade aluminum with certified material reports

2. Precision Tooling: Diamond-coated end mills for superior surface finishes (Ra .8μm achievable)

3. Coolant Management: High-pressure coolant systems prevent thermal deformation

4. Quality Verification: CMM inspection and surface roughness testing for every batch

AOOM's Technical Advantages

Our CNC machining facility features:

- 20+ Swiss-type CNC lathes with live tooling

- 5-axis simultaneous machining centers

- Automated robotic loading for 24/7 production

- ISO 9001:2015 certified quality system

Applications of Precision Aluminum Components

From heat sinks with complex fin structures to aircraft mounting brackets, our CNC-machined aluminum parts serve critical functions in:

• Medical equipment housings

• Robotics articulation joints

• Optical instrument frames

• Electric vehicle battery enclosures

Contact AOOM Technology at www.aoomtech.com for your precision aluminum machining projects. Our engineering team provides DFM analysis and rapid prototyping services to ensure optimal manufacturability.