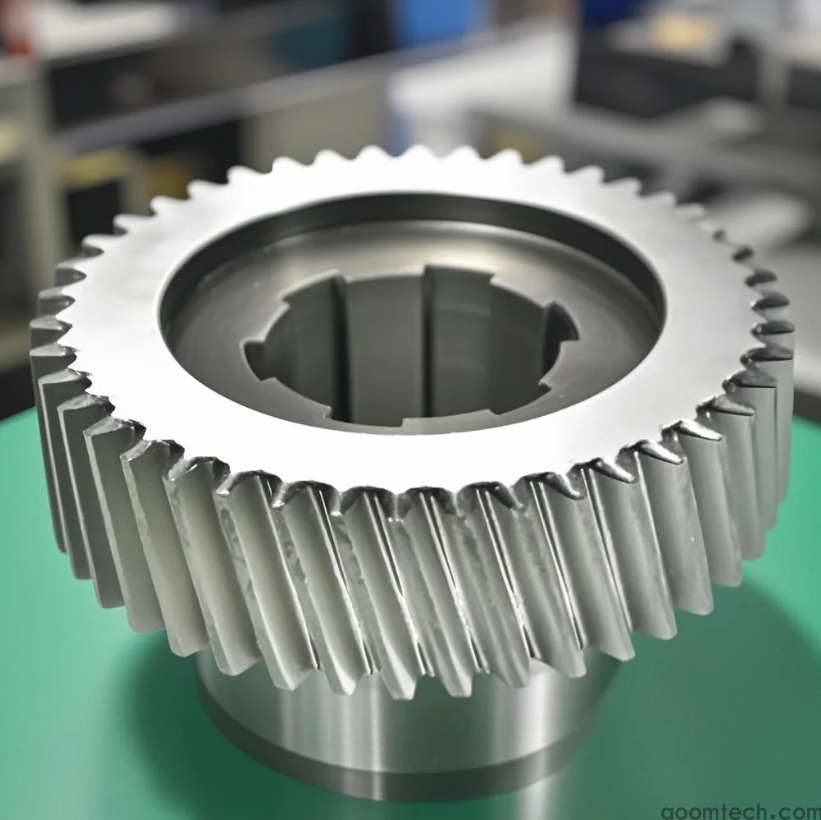

CNC Custom Machining Gears: Precision Engineering for Optimal Performance

In modern manufacturing, CNC custom machining gears represent a critical solution for industries requiring high-precision motion transmission components. As a leading CNC machining service provider, AOOM Technologies specializes in delivering gear solutions that meet exact specifications with micron-level accuracy.

Why Choose CNC Machining for Custom Gears?

CNC technology enables the production of gears with complex geometries, tight tolerances (up to ±.005mm), and superior surface finishes. Our 5-axis CNC machines at AOOM can manufacture:

Spur gears, helical gears, bevel gears, and worm gears

Custom gear profiles for specialized applications

Prototypes and high-volume production runs

Materials for CNC Machined Gears

We work with various materials to meet different operational requirements:

Metal gears: Aluminum, steel, stainless steel, brass, and titanium

Plastic gears: POM, Nylon, PTFE, and Peek

Exotic materials for extreme conditions

The AOOM Advantage in Gear Manufacturing

Our CNC custom machining process ensures:

Precision tooth profiles with smooth engagement

Consistent quality across production batches

Fast turnaround (as quick as 5 days for prototypes)

Competitive pricing with DFM analysis to optimize costs

With ISO 9001-certified processes and advanced metrology equipment, AOOM guarantees gears that perform reliably in automotive, robotics, aerospace, and industrial applications. Contact our engineering team today to discuss your gear requirements.