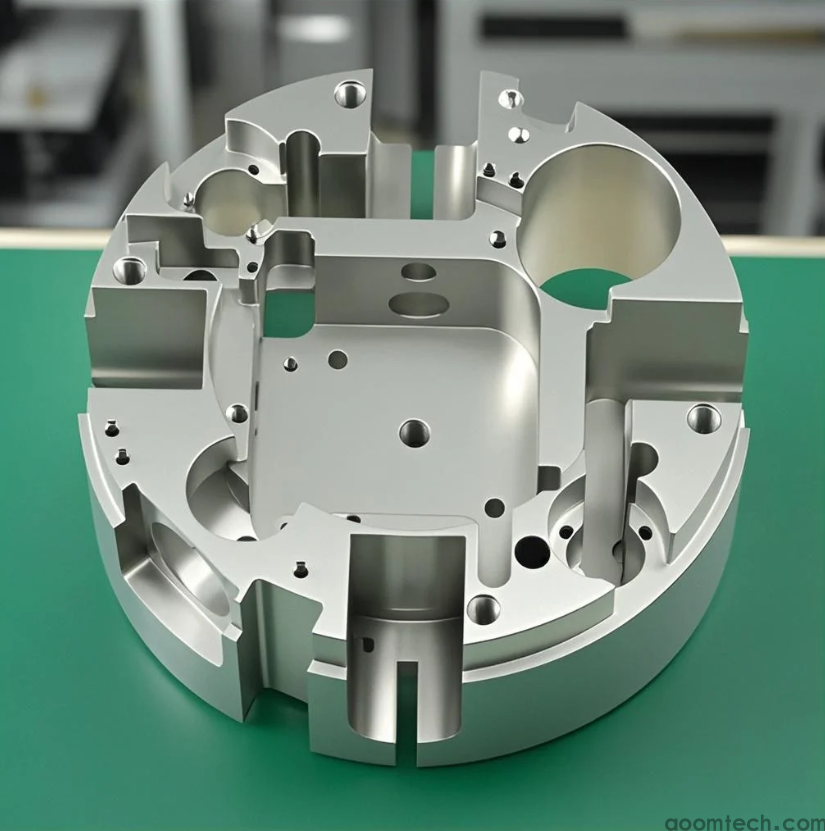

CNC High Precision Product Machining

What Is CNC High Precision Product Machining?

CNC high precision product machining refers to the advanced manufacturing process that utilizes computer numerical control systems to achieve exceptionally tight tolerances (typically within ±.001mm to ±.005mm) and superior surface finishes. At AOOM, we specialize in delivering such precision for industries including aerospace, medical devices, and optical equipment where dimensional accuracy is critical.

Key Advantages of Our High Precision CNC Services

Our CNC machining center combines state-of-the-art equipment with ISO 9001-certified processes to ensure:

Micro-level accuracy for complex geometries

Repeatable consistency across production runs

Superior surface finishes up to Ra .2μm

Material versatility (aluminum alloys, titanium, engineering plastics)

Technical Capabilities at AOOM

We operate 5-axis CNC machining centers with:

Linear scales for closed-loop position feedback

High-speed spindles (up to 30,000 RPM)

Temperature-controlled machining environment

On-machine probing for in-process verification

This infrastructure allows us to maintain the strictest tolerances for high precision products.

Quality Assurance Process

Every precision machined component undergoes:

First-article inspection with CMM (Coordinate Measuring Machine)

Statistical process control monitoring

Surface roughness testing

Material certification verification

Our metrology lab is equipped with Zeiss Contura G2 CMM and Mitutoyo roundtest instruments.

Industry Applications

Our precision machining serves:

Aerospace: Engine components, landing gear parts

Medical: Surgical instruments, implant components

Automotive: Fuel injection systems, transmission parts

Electronics: Connector housings, waveguide components

Visit AOOM's official website to explore our full capabilities and request a precision machining quote today.