CNC Machining for Dust Removal Equipment Parts

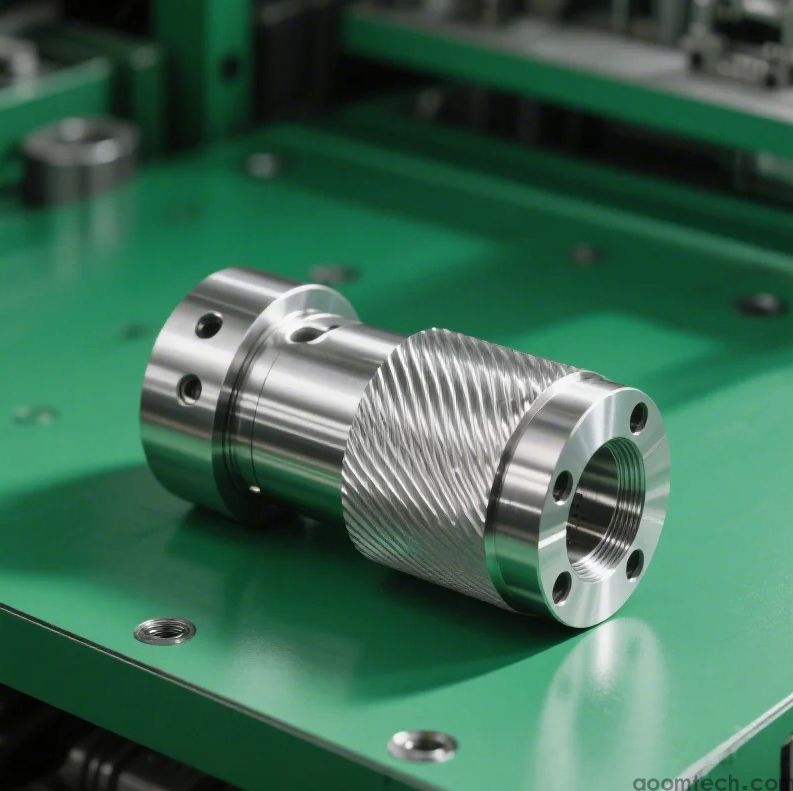

As a leading CNC machining service provider, AOOM specializes in manufacturing high-precision components for industrial applications, including dust removal equipment parts. This article explores the technical requirements, material selection, and quality control processes involved in producing these critical components.

Why Choose CNC Machining for Dust Removal Equipment Parts?

Dust collection systems require components with exceptional dimensional accuracy and surface finish to ensure airtight sealing and optimal performance. CNC machining offers superior precision (±.005mm) compared to conventional manufacturing methods, making it ideal for producing:

Blower housings

Impeller wheels

Duct connectors

Filter mounting frames

Material Selection for Durability

We recommend:

Aluminum 6061 (lightweight, corrosion-resistant)

Stainless steel 304/316 (for high-temperature applications)

Engineering plastics (POM, PTFE for chemical resistance)

AOOM's Manufacturing Advantages

Our 15,000㎡ facility features:

5-axis CNC machines for complex geometries

In-house CMM inspection (Zeiss Contura G2)

ISO 9001-certified quality system

Prototype to mass production capability

With extensive experience in dust removal equipment parts manufacturing, AOOM ensures your components meet strict industry standards while optimizing production efficiency and cost-effectiveness.