CNC Valve Machining Process

As a professional CNC valve machining service provider, AOOM Technology specializes in delivering precision-engineered valve components for industries ranging from oil & gas to aerospace. This article explores the technical nuances of valve manufacturing through CNC processes.

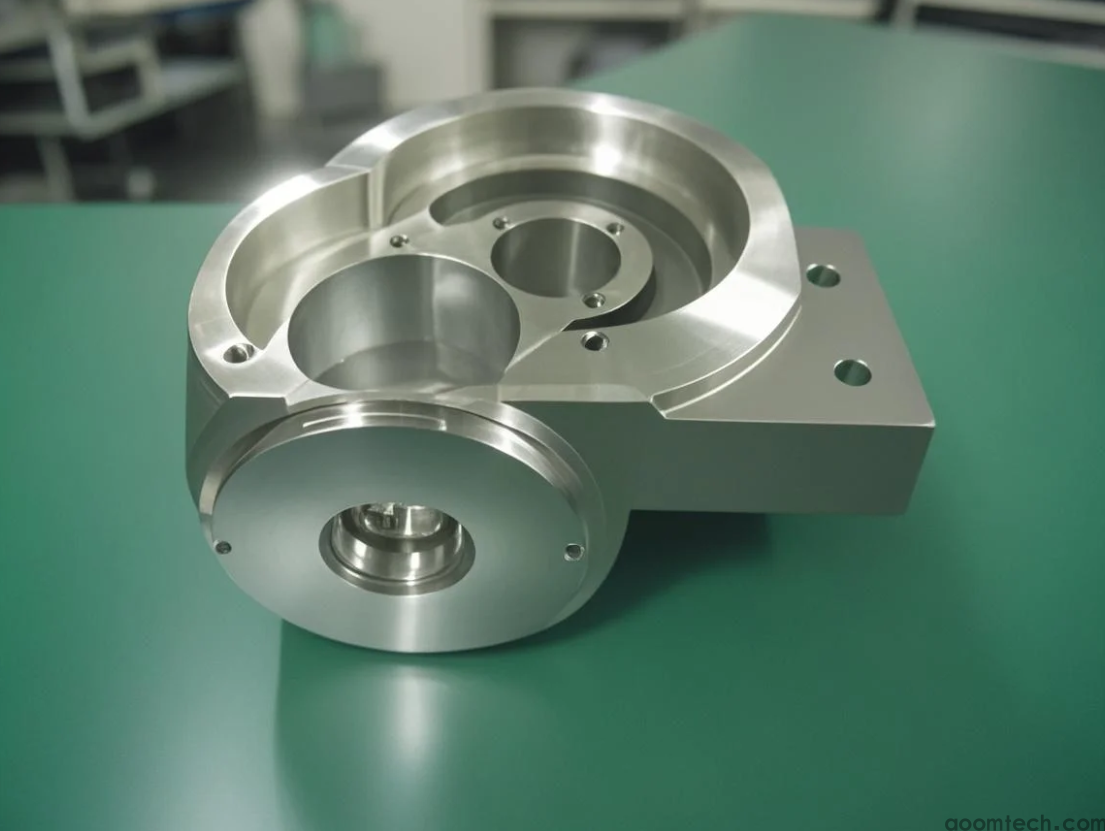

Understanding CNC Valve Machining

CNC valve machining involves subtractive manufacturing of valve bodies, stems, discs, and seats using computer-controlled equipment. The process ensures dimensional accuracy within ±.01mm, critical for leak-proof performance in high-pressure applications.

Key Advantages of Our CNC Valve Solutions

1. Material Versatility: Machining brass, stainless steel (304/316), duplex steels, and superalloys like Inconel

2. 5-Axis Capability: Complex internal porting and spherical surfaces machining

3. Surface Finishes: Ra .4μm mirror finishes for sealing surfaces

Quality Assurance Protocol

Every valve component undergoes:

- CMM inspection (Mitutoyo Crysta-Apex S)

- Pressure testing up to 10,000 PSI

- CNC machining process validation per ASME B16.34 standards

Visit AOOM Technology to request a free DFM analysis for your valve projects. Our engineering team combines 15+ years of CNC expertise with ISO 9001-certified production systems.