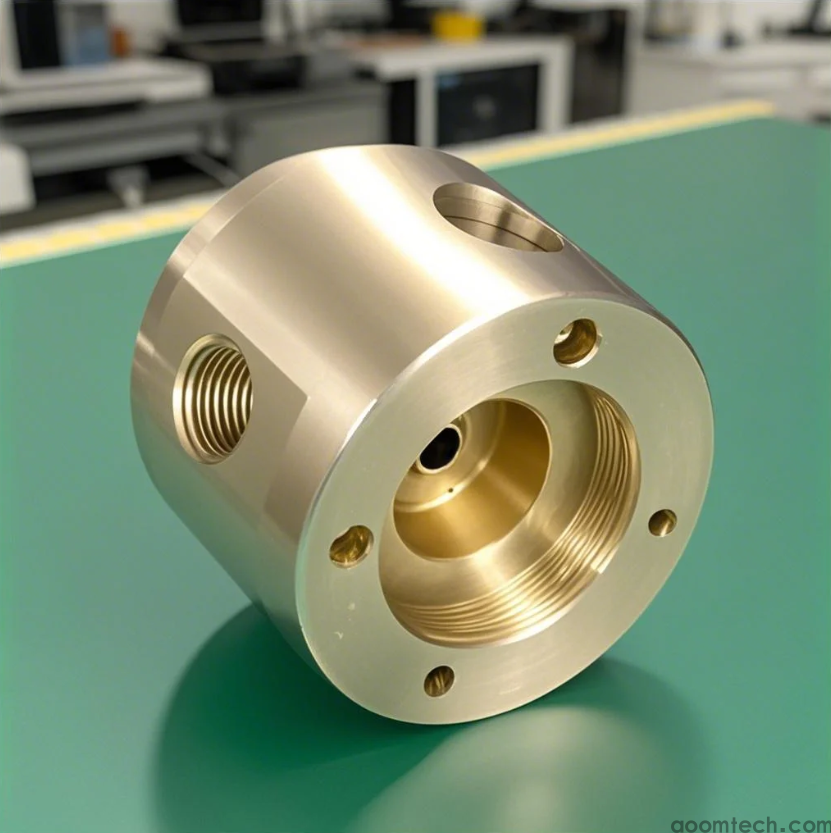

CNC Machining Joint Fittings

In precision manufacturing, CNC machining joint fittings represent critical components that demand exceptional accuracy and durability. As a leading CNC machining service provider, AOOM Technologies delivers industry-leading solutions for complex joint fitting applications across aerospace, automotive, and industrial sectors.

What Are CNC Machined Joint Fittings?

Joint fittings manufactured through CNC processing are precision-engineered connectors designed for load-bearing applications. Our 5-axis CNC machines produce these critical components with tolerances as tight as ±.005mm, ensuring perfect mating surfaces and optimal mechanical performance.

Technical Advantages of AOOM's CNC Joint Fittings

1. Material Versatility: We machine joint fittings from aluminum alloys, stainless steel, titanium, and engineering plastics

2. Surface Finish Options: From Ra .8μm mirror finishes to specialized coatings

3. Complex Geometry Capability: Internal threading, undercuts, and multi-angle bores

4. Rapid Prototyping: 3-5 day turnaround for functional prototypes

Quality Assurance Process

Every joint fitting undergoes rigorous inspection including CMM measurement, pressure testing, and metallurgical analysis. Our ISO 9001-certified facility maintains full traceability from raw material to finished product.

Industry Applications

• Hydraulic/pneumatic systems

• Robotics articulation points

• Structural framework connections

• Precision instrumentation assemblies

Contact AOOM Technologies at www.aoomtech.com for your custom CNC joint fitting requirements. Our engineering team provides DFM analysis and cost optimization for every project.