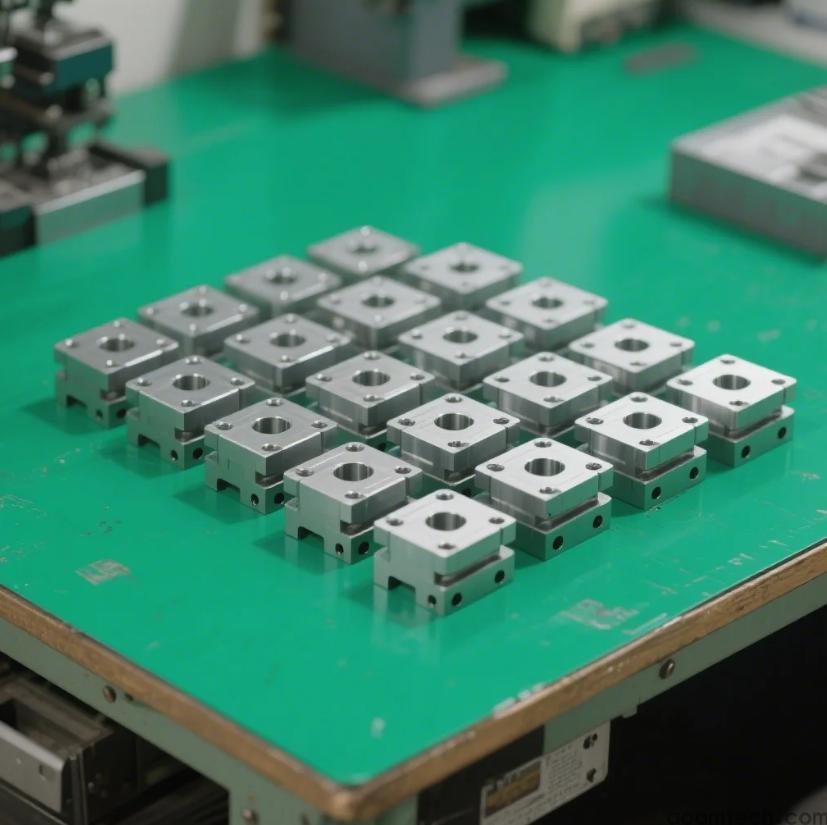

CNC Air Cooler Parts Machining

As a leading CNC machining service provider, AOOM Technology specializes in manufacturing precision CNC air cooler parts for various industrial applications. This article will explore the technical process, material selection, and quality control measures that ensure superior performance of these critical components.

Understanding CNC Air Cooler Components

Air cooler systems rely on precisely machined parts including heat sinks, fan housings, mounting brackets, and fluid channels. Our 5-axis CNC machines can produce these components with tolerances as tight as ±.005mm, ensuring perfect fit and optimal thermal performance.

Material Selection for Durability

We machine air cooler parts from:

Aluminum 6061/7075 (for lightweight corrosion resistance)

Copper C110 (for superior heat transfer)

Stainless steel 303/304 (for high-temperature applications)

Advanced Machining Processes

Our manufacturing workflow includes:

3D modeling and DFM analysis

High-speed milling with coolant optimization

Precision drilling for airflow channels

Surface finishing (anodizing, powder coating, or polishing)

Quality Assurance Protocol

Every batch undergoes:

CMM inspection for dimensional accuracy

Thermal performance testing

Pressure testing for sealed components

100% visual inspection

Why Choose AOOM Technology?

With 15+ years in precision machining, we offer:

Fast turnaround (prototypes in 3-5 days)

Competitive pricing for bulk orders

Engineering support for design optimization

ISO 9001-certified production

Visit our website www.aoomtech.com to request a free quotation for your custom CNC air cooler parts project.